| Brand: | Bermad |

| Category: | Control Valves, 100 Series |

| Size Range: | 40-150mm |

| Connection: | 40-80mm - Female Threaded BSP 80-150mm - Flanged |

| Engineering Data: |

Product Description

The BERMAD Model 130-55-X 3 Way Pressure sustaining valve is a hydraulically operated, diaphragm-actuated control valve that sustains minimum preset upstream (back) pressure and opens fully when line pressure is in excess of setting. It either opens or shuts in response to an electric signal.

Features and Benefits

- Line Pressure Driven, Electrically Controlled On/Off

- Prioritizes pressure zones & controls system fill-up

- Sustains upstream line pressure

- Opens fully upon line pressure rise

- Engineered Plastic Valve with Industrial Grade Design

- Highly durable, chemical and cavitation resistant

- No internal bolts and nuts

- hYflow ‘Y’ Valve Body with "Look Through" Design

- Ultra-high flow capacity –Low-pressure loss

- Unitized Flexible Super Travel (FST) Diaphragm and Guided Plug

- Accurate and stable regulation with the smooth closing

- Requires low actuation pressure

- Prevents diaphragm erosion and distortion

- Simple In-Line Inspection and Service

1. BERMAD Model IR-130-55-X opens in response to an electric signal, sustains supply system pressure preventing emptying, and controls laterals and distribution lines fill-up

2. BERMAD Air Valve Model ARA-A-P-P

3. BERMAD Solenoid Controlled Valve Model IR-110-N1-2W

4. BERMAD Vacuum Breaker Model ½"-ARV

Typical Applications

- Computerized Irrigation Systems

- Line Fill-Up Control Solutions

- Line Emptying Prevention

- Remote and/or Elevated Plots

- Infield Filters Backwash Pressure Sustaining

- Energy Saving Irrigation Systems

Technical Data

Operation

The Shuttle Valve [1] hydraulically connects the Solenoid [2] or the Pressure Sustaining Pilot (PSP) [3] to the Valve Control Chamber [4]. When the solenoid is closed, the PSP commands the Valve to throttle closed should Upstream Pressure [P1] drops below the setting and open fully when [P1] rises above the setting. In response to an electric signal, the solenoid switches, directing line pressure through the shuttle valve into the control chamber, thereby causing the main Valve to shut. The solenoid also features local manual closing.

Materials

Body, Cover and Plug

- Glass-Filled Nylon

Diaphragm

- NR, Nylon Fabric Reinforced

Seals

- NR

Spring

- Stainless Steel

Cover Bolts

- Stainless Steel

Control Accessories

- Plastic

Tubing and Fittings

- Plastic

Valve Configurations & Size

- Oblique: DN50, 65, 80, 80L, 100 & 150

- Angle: DN80

End Connections

- 40-80mm - Female Threaded BSP

- 80-150mm - Flanged

Pressure Rating

- 10 bar.

Operating Pressure Range

- 0.35-10 bar.

Setting Range

- 1-7 bar.

Setting ranges vary according to specific pilot springs. Please consult Deeco.

Solenoid Voltage Range

- S-390 & S-400: 24 VAC, 24 VDC

- S-392 & S-402: 9-20 VDC, Latch

- S-982 & S-985: 12-50 VDC, Latch

Other voltages are available.

Flow Chart

Bermad - 130-55-3W - Flow Chart

Technical Specifications

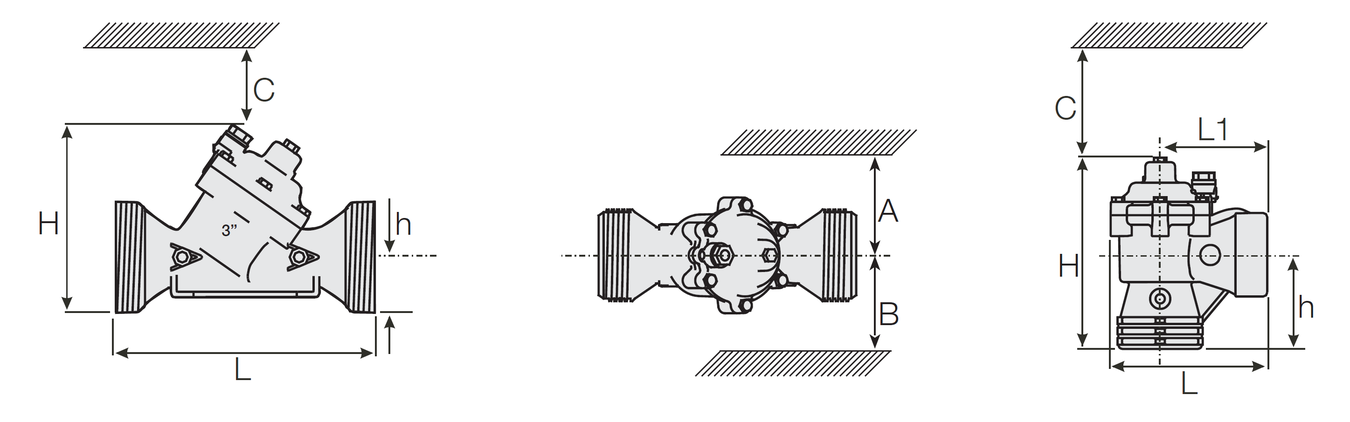

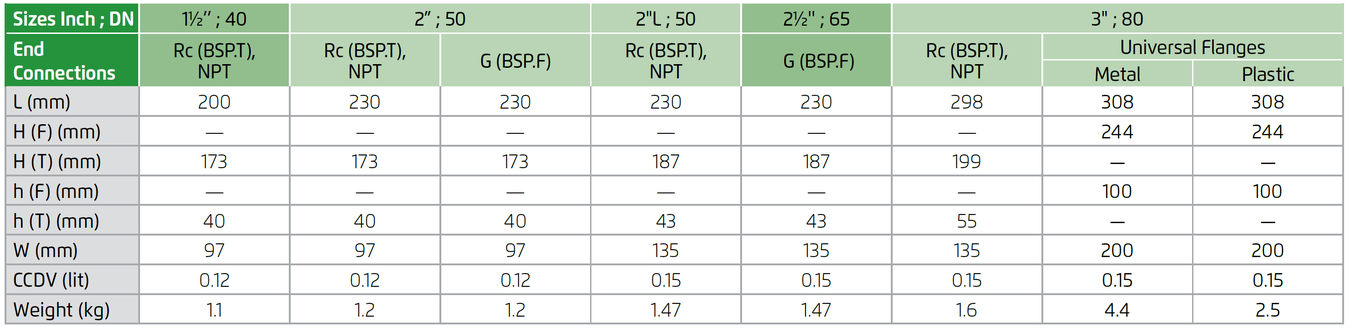

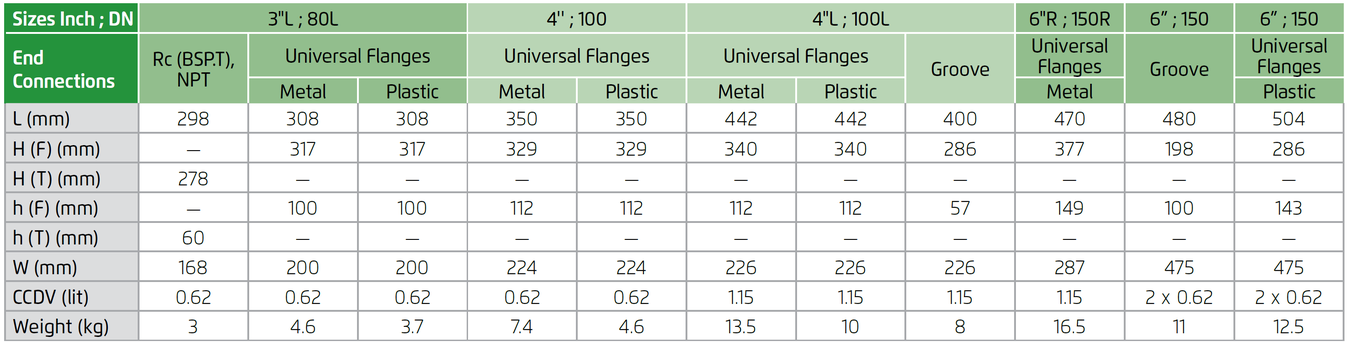

Dimensions and Weights

* DN65 Male Thread BSP-F, for PVC glue Unions.

CCDV = Control Chamber Displacement Volume • BSP.T = Internal Threaded • BSP.F = External Threaded • Other End Connections are available on request. For dimensions and weights of adapters or valves with adapters please consult with customer service

For Spare Parts & Repair Kits - Please refer to the base model:

Due to the wide range of options available and criteria for correct model selection, pricing and configuration are available on application only.

Please consult with Deeco engineers for more information.