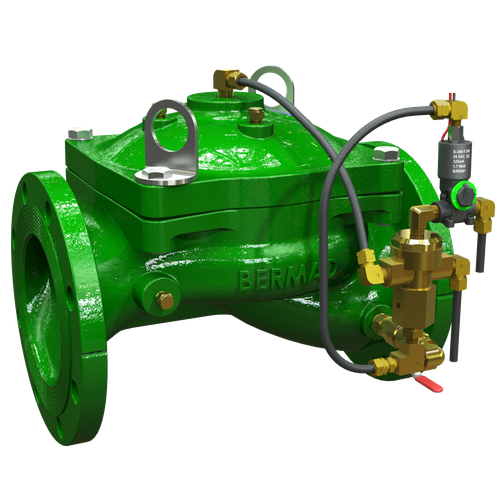

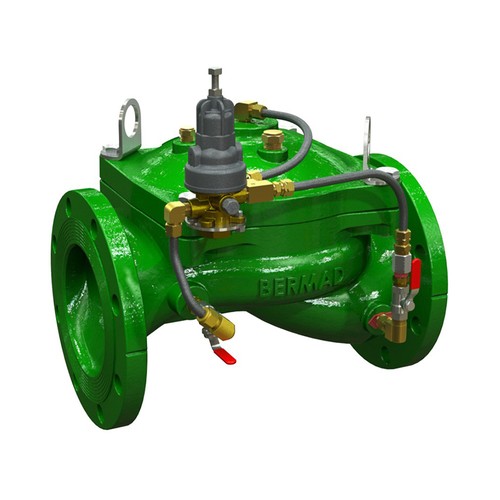

| Brand: | Bermad |

| Category: | Control Valves, 400 Series |

| Size Range: | 25-300mm |

| Connection: | 25-80mm - Female Threaded BSP 80-300mm - Flanged |

Product Description

The 400 Series is designed for agricultural irrigation. The patented and design-registered 400 Series represents the cutting edge of control valve technology. This diaphragm-actuated family of valves blends simple, dependable construction with superior performance for versatility in a range of water control applications in irrigation and waterworks systems.

IR - 400 Basic Valve

The basic Mode IR-400 diaphragm actuated hydraulically operated valve is at the leading edge of a control valve design. It combines simple and reliable construction with superior performance, while at the same time being virtually free of the typical limitations associated with other single-chambered valves. These automatic water control valves are designed for vertical or horizontal installation and are available in diameter sizes of a DN50-DN400, in a wide range of materials and end connections.

The design of the IR-400 valve body includes a full-bore seat with unobstructed flow path, free of any in-line ribs, supporting cage, or shafts.

The unique hydro-dynamic glove design provides high flow capabilities with minimum head loss. The cover is removable via (4) fastening bolts (up to 10") for quick in-line inspection and service. The internal design of the IR-400 valve is based on innovative technology using advanced rubber-based materials to achieve a solid, one-piece elastomeric assembly including a flexible fabric-reinforced diaphragm, vulcanized with a rugged radial seal disk.

The diaphragm is carefully balanced and peripherally supported to avoid distortion and to protect the elastomer, resulting in long life and controlled actuation even under harsh conditions. One diaphragm and spring fully meet the valve's operating pressure range requirements. The diaphragm assembly can be easily removed from the valve body with no need for disassembling the valve from the line.

The Model IR-400 Basic Valve uses valve differential pressure to power the diaphragm assembly open or closed. The lower side of the diaphragm, which serves to cushion the closing of the valve, is exposed to downstream pressure through a dynamic peripheral passageway that its width responds to differential pressure and flow along the downstream side of the valve.

Features & Benefits

- Hydraulic Control Valve

- Line pressure driven

- Hydraulically controlled On/Off

- Advanced Globe Hydro-Efficient Design

- Unobstructed flow path

- Single moving part

- High flow capacity

- Fully Supported & Balanced Diaphragm

- Requires low opening and actuation pressure.

- Progressively restrains valve closing.

- Prevents diaphragm distortion.

- User-Friendly Design

- Simple in-line inspection

- Easy addition of control features

Typical Applications

- Computerized Irrigation Systems

- Distribution Centers

- LPS - Low Pressure Systems

- Level Control Valves

- Filter Stations

Technical Data

Principle Of Operation

ON-Off Modes

Closed Position:

Line Pressure applied to the control chamber of the valve creates a hydraulic force that moves the valve to the closed position and provides drip tight sealing.

Open Position:

Discharging the pressure from the control chamber to atmosphere or some other lower pressure zone, causes the line pressure acting on the plug to open the valve.

2-way Modulating Modes

Modulating Closed:

The restriction continuously allows line pressure into the control chamber. The pilot controls outflow from the control chamber. Throttling when it senses a pressure rise, it causes pressure to accumulate in the control chamber, thereby forcing the valve to modulate closed.

Modulating Open:

The Pilot modulates open when it senses a pressure drop releasing more flow from the control chamber than the restriction can allow in. This causes the accumulated pressure in the control chamber to drop, and the valve modulates open.

Zero Slow Position:

When demand drops to zero, downstream pressure begins to rise as the flow enters a closed line. The pilot closes initiating a valve's irreversible closing process, eventually casing it to seal drip tight.

3-Way Control Modes

Fully Open Position:

When Upstream Pressure drops, the pilot blocks the pressure port and opens the drain port, venting the control chamber to the atmosphere. This fully open the valve, Minimizing Head loss.

Modulating Closed:

The pilot switches upon pressure rise, blocking the drain port and opening the pressure port. This pressurizes the control chamber, forcing the valve to modulate closed.

Locked Position:

When sensed pressure is equal to setting, the pilot shaft moves and blocks both the drain port and the pressure port. This locks the pressure in the control chamber, freezing the valve in its last position until condition change.

Zero Flow Position:

When Demand drops to zero, downstream pressure begins to rise as the flow enters a closed line. The pilot switches and pressurizes the control chamber initiating a valve's irreversible closing process, eventually causing it to seal drip tight.

Exploded View

[1] Fastening Bolts

Only four bolts (up to 10"; DN250 Valve) fasten valve cover to body, ensuring quick in-line inspection and service.

[2] Valve Cover

Locates, centralizes and fastens diaphragm and spring ensuring smooth and accurate performance. Simple construction enables quick in-line inspection and service.

[3] Auxiliary closing Spring.

One single spring fully meets valve requirements for operating pressure range, ensuring low opening pressure and secured closing.

[4] Diaphragm Assembly

One-piece elastomeric assembly that includes a peripherally supported flexible diaphragm, vulcanized with a rugged radial seal disk.

- No need for special Tyres of diaphragms to meet different operating conditions.

- Progressive dynamic guidance, resulting in exceptionally stable action and restrained closing.

- Valve opens and closes drip tight even with very low-pressure supply.

- Perfectly balanced diaphragm with no distortion caused by uneven hydraulic forces on shut off or during regulation.

- Exceptionally stable and chatter-free action during shut-off and pressure regulation.

[5] Body Threads

No need for nuts, simplifying valve disassembling and assembling for maintenance.

[6] Wide Body valve

Hydro-dynamically designed for efficient flow with minimal pressure loss and excellent resistance to cavitation.

[6.1] Diaphragm Supporting & Guiding

[6.2] Diaphragm Balancing Chamber

[6.3] Valve Seat: Full bore, valve port area clear of obstructions; no ribs or stem guides. Flow entrance is vertical to seal disk.

[6.4] End connections: Conforms to pressure ratings and standards of: ISO, ANSI, JIS, BS, and others.

Standard Materials

- Castings & Forgings:

- Cast Iron to EN 1561

- Ductile Iron to EN 1563

- Brass

- Elastomers: NR to EN 681-1

- Coatings: Electrostatic Powder Coating Polyester

Connections Standard:

- Flanged: Table D

- Threaded: BSP

Operating Pressure Ranges:

- IR-400: 0.5-16 bar (For lower pressure requirements, consult Deeco).

- Temperature: Water up to 60°C

Flow Chart

Globe Pattern

2-Way circuit "Added Head Loss" (for "V" below 2 m/s; 0.3 bar)

Angle Pattern

Technical Specifications

Dimensions and Weights

Globe Pattern

Angle Pattern

Spare Parts

| Pos. | Product Code | Size | Product Description |

|---|---|---|---|

1 |

405025-2 |

25mm |

Diaphragm for 400 Series Valve - 66mm Diameter |

2 |

405040-2 |

40mm |

Diaphragm for 400 Series Valve - 84mm Diameter |

3 |

405050-2 |

50mm |

Diaphragm for 400 Series Valve - 110mm Diameter |

4 |

405065-2 |

65-80Rmm |

Diaphragm for 400 Series Valve - 122mm Diameter |

5 |

405080-2 |

80mm |

Diaphragm for 400 Series Valve - 157mm Diameter |

6 |

405100-2 |

100mm |

Diaphragm for 400 Series Valve - 189mm Diameter |

7 |

4050150-2 |

150mm |

Diaphragm for 400 Series Valve - 270mm Diameter |

8 |

4050200-2 |

200-250mm |

Diaphragm for 400 Series Valve - 346mm Diameter |

| Pos. | Product Code | Size | Product Description |

|---|---|---|---|

1 |

405025-4 |

25mm |

Spring - 400 Series Valve |

2 |

405040-4 |

40mm |

Spring - 400 Series Valve |

3 |

405050-4 |

50mm |

Spring - 400 Series Valve |

4 |

405065-4 |

65-80Rmm |

Spring - 400 Series Valve |

5 |

405080-4 |

80mm |

Spring - 400 Series Valve |

6 |

405100-4 |

100mm |

Spring - 400 Series Valve |

7 |

405150-4 |

150mm |

Spring - 400 Series Valve |

8 |

405200-4 |

200-250mm |

Spring - 400 Series Valve |

| Pos. | Product Code | Description |

|---|---|---|

1 |

FT8 |

Bermad 8mm PE Control Valve Tubing - Per Meter |

2 |

FT18 |

Bermad 8 mm Straight Tube/Thread 1/8" |

3 |

FT28 |

Bermad 8mm - Elbow Tube/Thread 1/8" |

4 |

FT58 |

Bermad 8mm Elbow Tube/Thread 1/4" |

5 |

FT88 |

Bermad 8mm Connector Tube/Tube |

6 |

FT98 |

Bermad 8mm Tee Connector Tube/Tube/Tube |

7 |

FT98/1 |

Bermad 8mm Tee Connector Tube/Thread/Tube. 1/8" |

8 |

FT98/1-FT |

Bermad 8mm Tube Orifice Tee Connector. Tube/Thread/Tube. 1/8" with 1.0mm restrictor |

9 |

FT48 |

Bermad Thread/Thread Reducer. 1/4"M x 1/8"F |

10 |

FT38 |

Bermad Plug. Threaded BSP 1/8" |

11 |

FT34 |

Bermad Plug. Threaded BSP 1/4" |

12 |

FTPS8 |

Bermad 8mm Pressure Selector. Tee Tube/Tube/Tube |

13 |

FF8PLR |

Bermad 1/4" x 1/8" Inline Finger Filter Plastic |

14 |

FF8SR |

Bermad 1/4" Inline Finger Filter Stainless |

Standard Adjustment Range 1-7 Bar with other spring ranges available on request

| Pos. | Product Code | Description |

|---|---|---|

1 |

PG63/6 |

Stainless Cased Oil Filled Pressure Gauge. 600kPA / 90PSI |

2 |

PG63/10 |

Stainless Cased Oil Filled Pressure Gauge. 1000kPA / 150 PSI |

3 |

PG63/16 |

Stainless Cased Oil Filled Pressure Gauge. 1600kPA / 230 PSI |

4 |

0310 |

Ravit Pressure Gauge Probe / Needle |

5 |

2020 |

Ravit Pressure Test Point / Valve |

6 |

SCHRADER |

Schrader Test Point |

7 |

SCHRADER GF |

Schrader pressure Gauge Fitting |

Due to the wide range of options available and criteria for correct model selection, pricing and configuration are available on application only.

Please consult with Deeco engineers for more information.