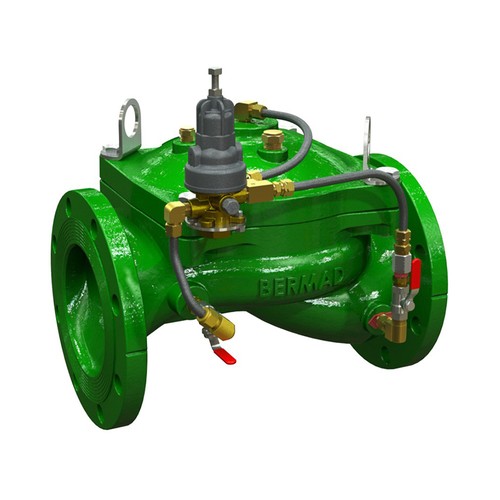

| Brand: | Bermad |

| Category: | Control Valves, 400 Series |

| Size Range: | 25-300mm |

| Connection: | 25-80mm - Female Threaded BSP 80-300mm - Flanged |

| Engineering Data: |

Product Description

The BERMAD Model 450-60-2 Way Level Control Valve with Modulating Horizontal Float is a hydraulically operated, diaphragm-actuated control valve. The valve hydraulically controls reservoir filling to maintain a constant water level regardless of fluctuating demand.

Features and Benefits

- Line Pressure Driven, Hydraulically Controlled

- Modulating Hydraulic Float Control

- “Always Full” reservoir

- Advanced Globe Hydro-Efficient Design

- Unobstructed flow path

- Single moving part

- High flow capacity

- Fully Supported & Balanced Diaphragm

- Requires low opening and actuation pressure

- Excellent low-flow regulation performance

- Progressively restrains valve closing

- Prevents diaphragm distortion

- External Installation

- Easy access to valve and float

- Less wear and tear

- Simple in-line inspection and service

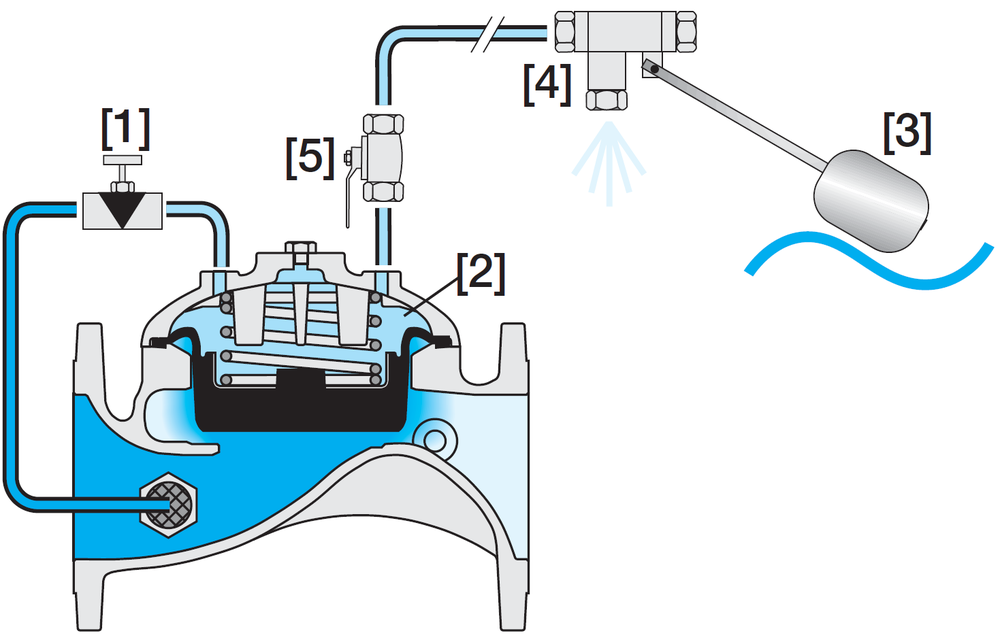

1. BERMAD Model IR-450-60-R opens upon a drop in reservoir level maintaining an

“Always Full” reservoir and shuts on a rise in reservoir level to preset high.

2. BERMAD Modulating Horizontal Float Model “60”

3. BERMAD Strainer Model 70F

Typical Applications

- Large Surface Area Reservoirs

- Low Volume Reservoirs

- Unavailable Power Supply Locations

- Fertilizer Mixing Tanks

Technical Data

Operation

The Needle Valve [1] allows continuous flow from the Valve inlet into the Control Chamber [2]. When the water level rises, it pushes the Float [3] up throttling the Float Pilot [4]. Pressure in the control chamber accumulates, causing the Valve to throttle closed, reducing the filling rate, and eventually closing the drip tight. Should the level fall, the float pilot releases pressure from the control chamber causing the Valve to modulate open. The needle valve controls the Valve closing speed. The Cock Valve [5] enables manual closing

Materials

Body and Cover

- Polyester Coated Cast or (DN250 and larger) Ductile Iron

Spring

- Stainless Steel

Diaphragm

- Nylon fabric Reinforced NR with rugged insert

Bolts, Studs, and Nuts

- Zinc-Cobalt plated Stee

Control Accessories

- Brass

Tubing and Fittings

- Reinforced Plastic and Brass

Pressure Rating

- 16 bar.

Operating Pressure Range

- 0.5-16 bar.

For lower pressure requirements, consult Deeco.

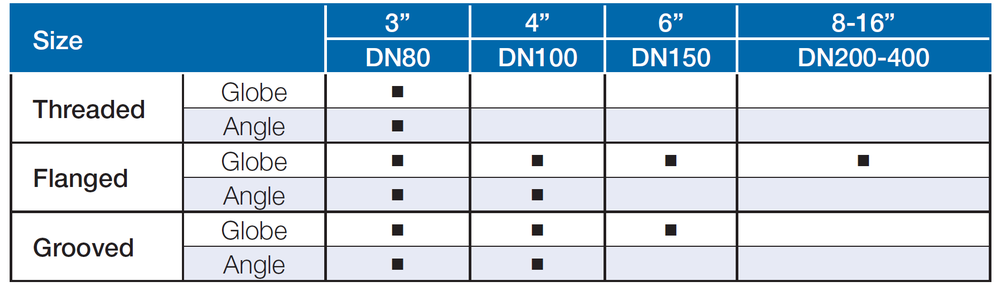

Patterns and Sizes

- Globe: DN80-400

- Angle: DN80-100

End Connections

- 25-80mm - Female Threaded BSP

- 80-400mm - Flanged

Bermad - 450-60-2W - End Connections

Technical Specifications

For technical specifications (Flow charts, valve characteristics, dimensions, etc.) - Please refer to the Engineering Data:

For Spare Parts & Repair Kits - Please refer to the base model:

Due to the wide range of options available and criteria for correct model selection, pricing and configuration are available on application only.

Please consult with Deeco engineers for more information.