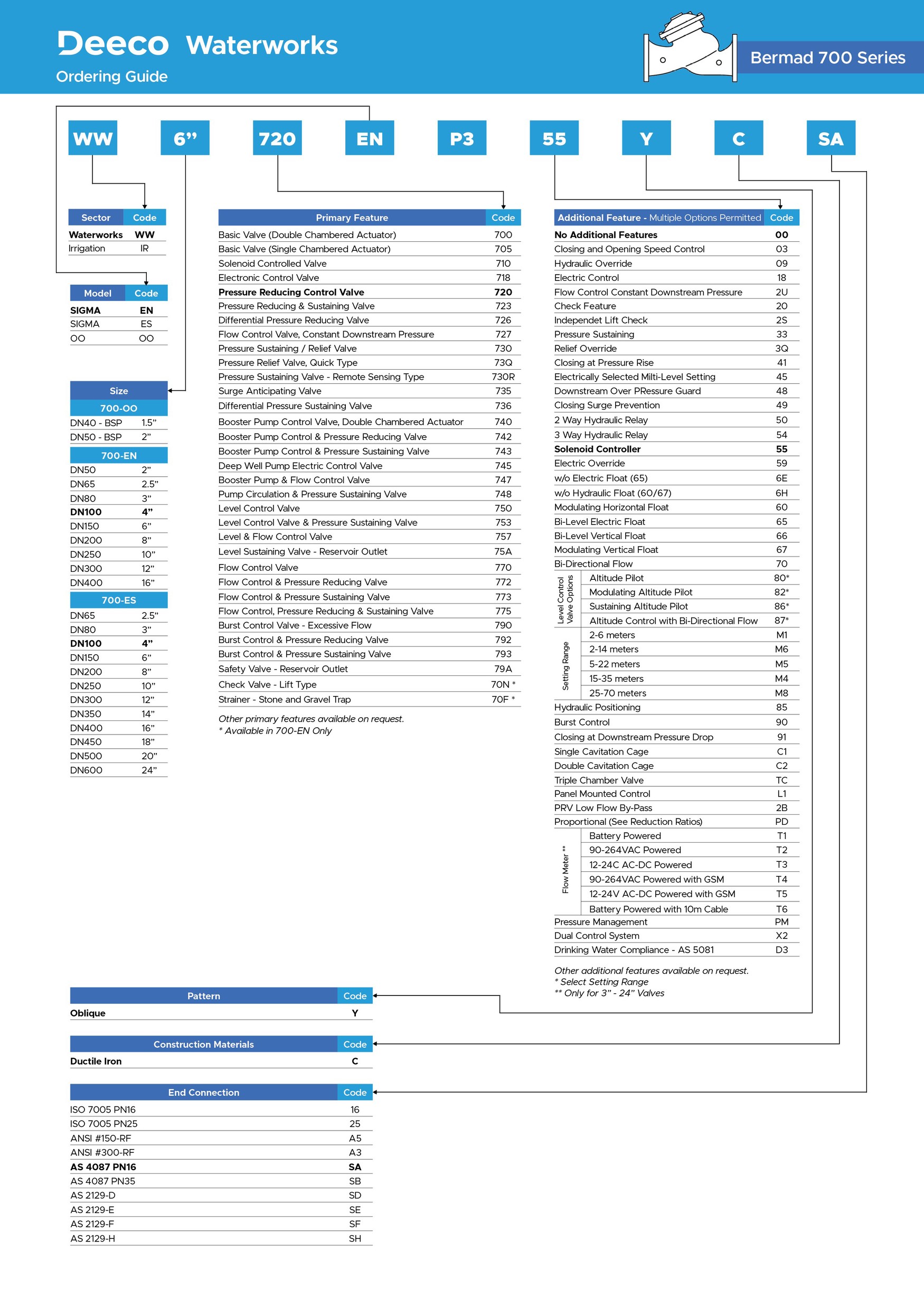

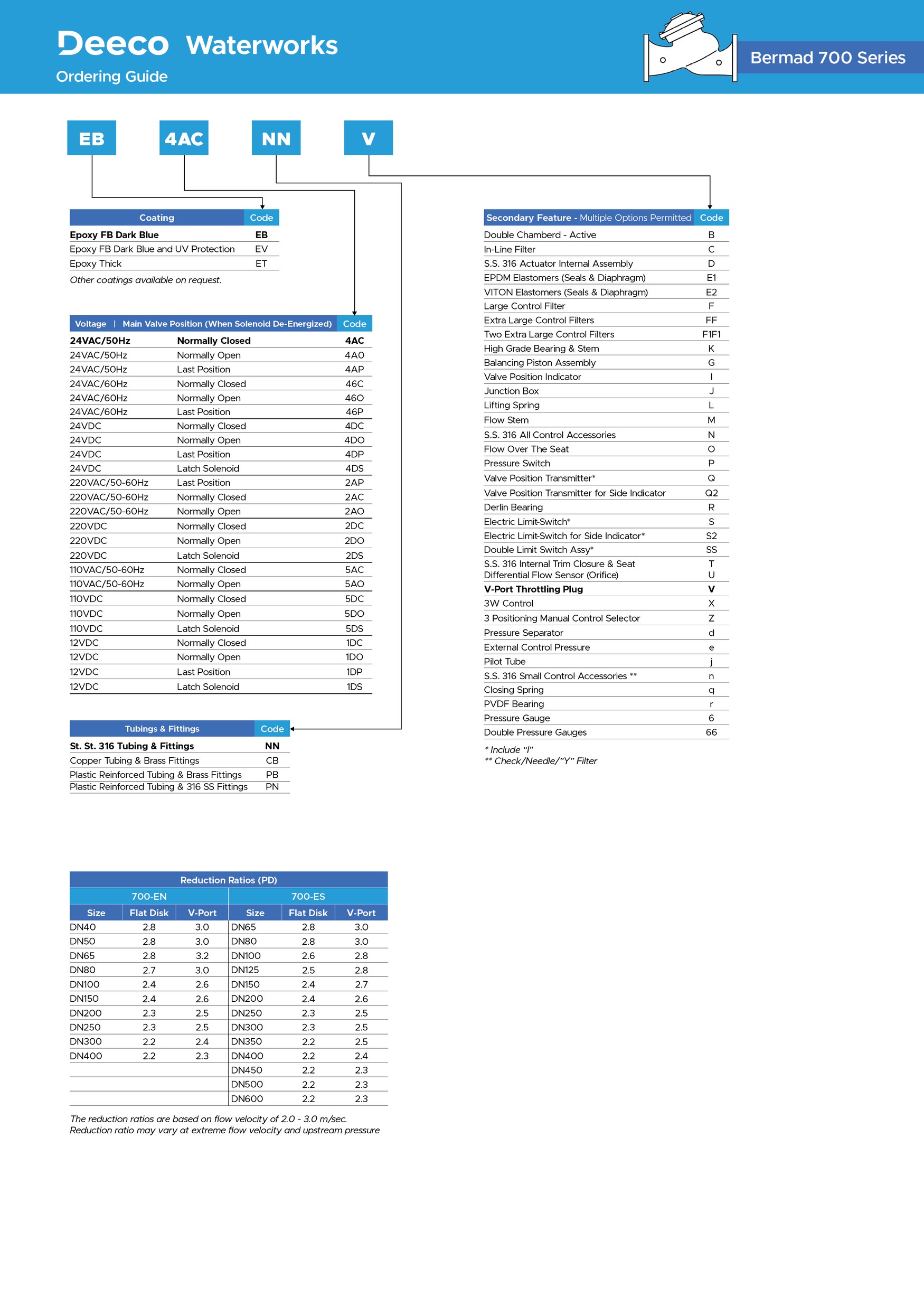

| Brand: | Bermad |

| Category: | Control Valves, 700 Series |

| Size Range: | 50-600mm |

| Connection: | EN: 50-400mm - Flanged ES: 65-600mm - Flanged |

| Engineering Data: |

Product Description

The Model 720-20 Pressure Reducing Valve with Check Feature is a hydraulically operated, diaphragm-actuated control valve that reduces higher upstream pressure to lower constant downstream pressure regardless of fluctuating demand or varying upstream pressure. The check feature prevents reverse flow through the valve.

- Flow and leakage reduction

- Cavitation damage protection

- Return flow prevention

- Throttling noise reduction

- Burst protection

Features and Benefits

- Line pressure driven – Independent operation

- Check feature

- Replacing line-sized check valve

- Cost-effective pumping

- One-way zonal back-up

- In-line serviceable – Easy maintenance

- Double chamber design

- Moderated valve reaction

- Protected diaphragm

- Flexible design – Easy addition of features

- Variety of accessories – Perfect mission matching

- “Y” or angle, wide-body – Minimized pressure loss

- Semi-straight flow – Non-turbulent flow

- Stainless Steel raised seat – Cavitation damage resistant

- Obstacle-free, full bore – Uncompromising reliability

- V-Port Throttling Plug – Low flow stability

Major Additional Features

- Pressure management valve –7PM-20

- Solenoid control & check valve – 720-25

- Downstream over pressure guard – 720-20-48

- High sensitivity pilot – 720-20-12

- Electrically selected multi-level setting – 720-20-45

- Electronic multi-level setting, Type 4T – 720-20-4T

- Automatic regulation override – 720-20-09

Typical Applications

Cost Effective Pumping

One zone of a distribution network has two supply sources. Setting the Model 720-20 Pressure Reducing Valve with Check Feature slightly higher than pump pressure, ensures pumping only when pressure provided from the network is insufficient. The Model 720-20:

- Protects the zone from excessive network supply pressure

- Saves energy and lowers costs by off-hours pumping

Bermad - Model 720-20 - Typical Application-Cost Effective Pumping

One-Way Zonal Backup

The Bermad Pressure Reducing Valve with Check Feature, installed between two pressure zones, permits one zone to backup pressure supply to another zone while preventing reverse flow

Typical Application-One Way Zonal Backup

Typical Installation

In addition to the Pressure Reducing Valve with Check Feature, BERMAD recommends the system also includes

- Strainer Model 70F, preventing debris from damaging valve operation

- Relief Valve Model 73Q, providing:

- Protection against momentary pressure peaks

- Visual indication of the need for maintenance

Typical Installation

Technical Data

Operation

The Model 720-20 is a pilot-controlled valve equipped with an adjustable, 2-way pressure-reducing pilot and two check valves. The restriction [1] continuously allows flow from the valve inlet into the upper control chamber [2]. The pilot [3] senses downstream pressure. Should this pressure rise above the pilot setting, the pilot throttles, enabling pressure in the upper control chamber to accumulate, causing the main valve to throttle closed, and decreasing downstream pressure to the pilot setting. Should downstream pressure fall below the pilot setting, the pilot releases accumulated pressure, and the main valve modulates open. The V-Port plug (optional) [4] increases the ratio of flow to stem travel, providing more accurate, stable, and smooth regulation. The integral orifice between the lower control chamber and valve outlet moderates valve reactions. Should downstream pressure exceed upstream pressure, check valve [5] allows downstream pressure into the upper control chamber while check valve [6] traps this pressure, together closing the main valve. The one-way flow control needle valve [7] stabilizes the valve’s reaction in hard regulation conditions, by restricting the flow out of the control chamber. The downstream cock valve [8] enables manual closing.

Pilot System Specifications

Standard Materials:

Pilot:

Body: Stainless Steel 316 or Bronze

Elastomers: Synthetic Rubber

Spring: Galvanized Steel or Stainless Steel

Tubing & Fittings:

Stainless Steel 316 or Copper & Brass

Accessories: Stainless Steel 316, Brass, and Synthetic Rubber Elastomers

Pilot Adjustment Range:

0.5 to 3.0 bar

0.8 to 6.5 bar

1 to 16 bar

5 to 25 bar

Notes:

- Inlet pressure, outlet pressure, and flow rate are required for optimal sizing and cavitation analysis

- Recommended continuous flow velocity: 0.3-6.0 m/sec.

- Minimum operating pressure: 0.7 bar. For lower pressure requirements consult Deeco.

Main Valve

Size Range: 50-600mm

End Connections (Pressure Ratings):

EN: 50-400mm - Flanged

ES: 65-600mm - Flanged

Others: Available on request

Valve Patterns: “Y” (globe) & angle, globe (DN600-900)

Working Temperature: Water up to 60°C.

Standard Materials:

Body & Actuator: Ductile Iron

Internals: Stainless Steel, Bronze & coated Steel

Diaphragm: Synthetic Rubber Nylon fabric-reinforced

Seals: Synthetic Rubber

Coating: Fusion Bonded Epoxy, RAL 5005 (Blue) approved for drinking water or Electrostatic Polyester Powder

Technical Specifications

For technical specifications (Flow charts, valve characteristics, dimensions, etc.) - Please refer to the Engineering Data:

Bermad - Model 700 - Sigma EN/ES - Engineering Data

For Spare Parts & Repair Kits - Please refer to the base model:

Due to the wide range of options available and criteria for correct model selection, pricing and configuration are available on application only.

Please consult with Deeco engineers for more information.