| Brand: | Bermad |

| Category: | Control Valves, Fire Protection Series |

| Size Range: | 40-400mm |

| Connection: | 40-400mm - Flanged 40-200mm - Grooved |

Product Description

The BERMAD model 43T is an elastomeric, pilot-operated, pressure-relief valve. Designed specifically for advanced fire protection systems and the latest industry standards. The 43T prevents damage from over-pressure in piping systems, maintaining a preset upstream pressure limit regardless of pressure peaks and fluctuating conditions. Due to exceptional reliability and low head loss, it is ideal for the relief of fire pump discharge. The 43T dependably relieves excess system pressure to the sump or atmosphere, meeting all NFPA, UL, and FM requirements for fire pump service. The 43T is also well-suited for maintaining foam concentrate discharge pressure for a balanced proportioning system. As an option, the 43T can be fitted with a valve position indicator that can include a limit switch suitable for Fire & Gas monitoring systems

Features and Benefits

- Safety and reliability

- Time-proven, simple, fail-safe actuation

- Single-piece, rugged, elastomeric diaphragm seal – VRSD technology

- An obstacle-free, uninterrupted flow path

- High discharge capacity

- No mechanical moving parts

- High performance

- Fast, smooth response to pressure fluctuations

- High flow capacity

- Approved for PN 25bar/365 psi

- Straight-through-flow Y-type bod

- Specifically designed for fire protection

- Face-to-face length standardized to ISO 5752, EN 558-1

- Meets the requirements of the industry standards

- Quick and easy maintenance

- In-line serviceable

- Fast and easy cover removal

Approvals

Additional Features

- Sea water compatibility

- Large control filter

- Position limit switches

Typical Applications

- Fire pump pressure relief

- Foam concentrate recirculation

- Centralized thermal pressure relief

- Zonal safety relief

Technical Data

Operation

The BERMAD Model 43T pressure control valve remains closed as long as the system pressure remains lower than the preset value. The preset pressure can be adjusted by way of the pilot adjusting screw [4] When the pilot valve [1] senses upstream pressure [2] higher than the preset value it opens releasing water pressure from the main valve control chamber [3] thus causing the 43T to open and thereby relieving excess system pressure to a reservoir or sump, preventing system overpressure. When inlet pressure falls, the pilot valve throttles, enabling pressure to accumulate in the control chamber. This causes the main valve to close further and sustain upstream pressure. An integral restrictor [5] controls the valve’s closing speed. For valves 8” and larger, an adjustable needle valve is provided.

System P&ID

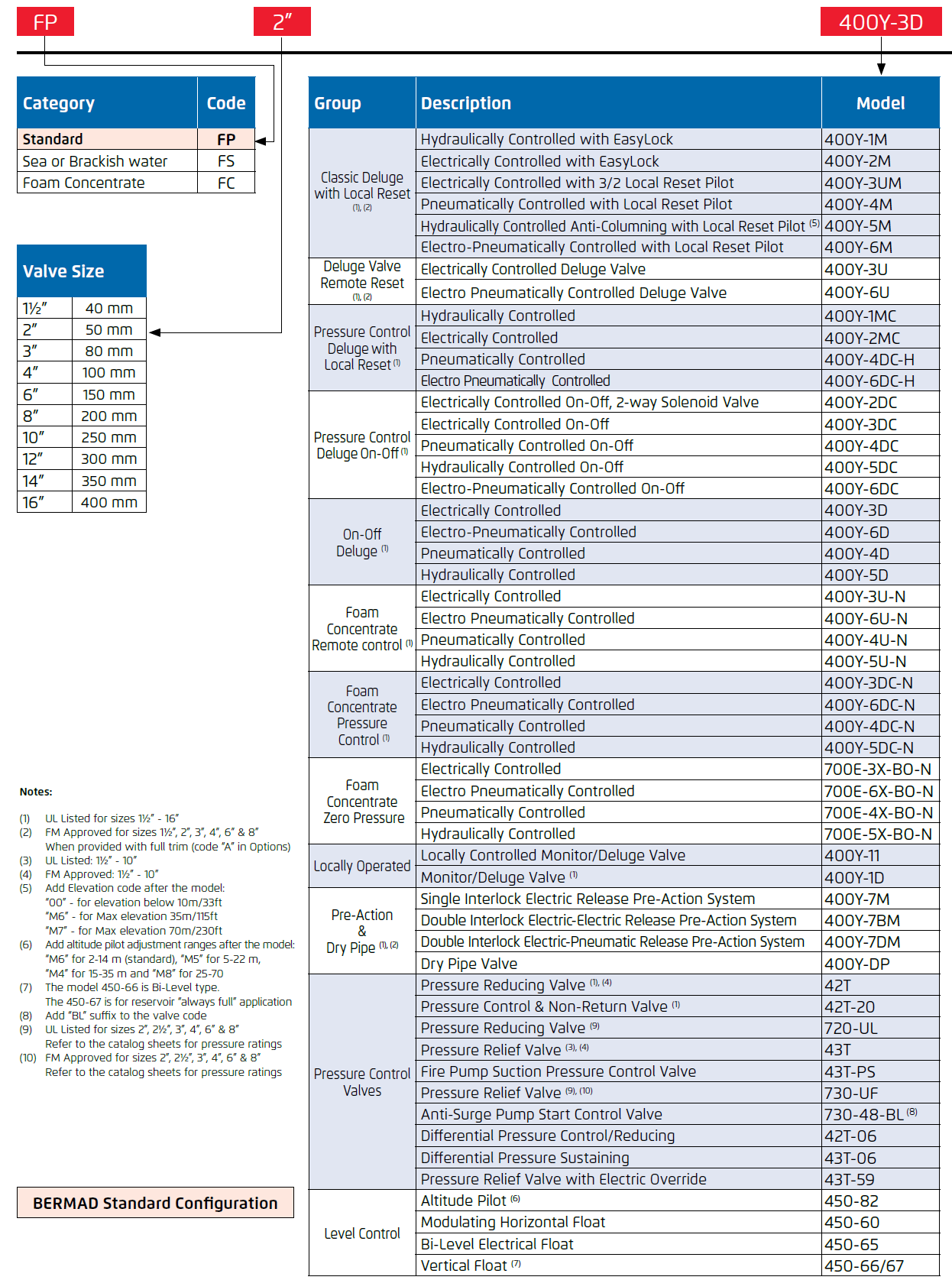

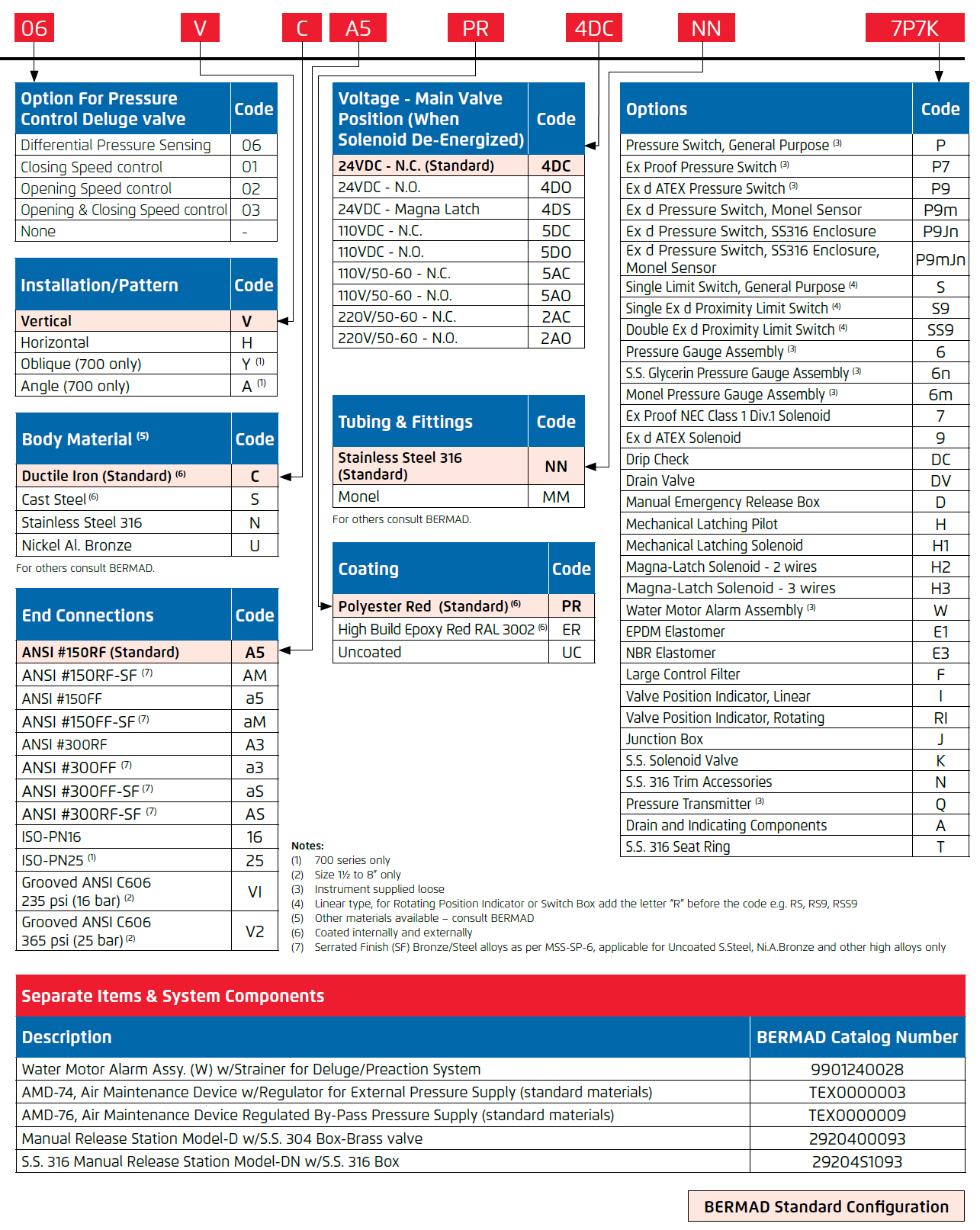

Components

1 BERMAD 400Y Water Control Valve

2 Y Strainer

3 Restriction Orifice

4 Pressure Relief Pilot Valve

5 Check Valve

Optional System Items

ZS Limit Switch Assembly

I Visual Indicator

Performance Table - Discharge Flow Chat

NOTE

- Use this chart to determine the valve size based on the design flow (GPM).

- For sizes greater than 10" please use information in Section 5.4.

- 43T pressure relief valves need to be installed as safety relief valves only. In systems using 43T where the pressure delta is greater than 175psi/12bar, please consult Victaulic engineering for guidance.

Main Valve

Available Sizes and Connection

- 40-400mm - Flanged

- 40-200mm - Grooved

Pressure Rating

- ANSI#150 - 16 bar / 235 psi

- ANSI#300 - 1½” to 10” 25 bar / 365 psi

12” to 16” 20 bar / 300 psi - Grooved/Threaded - Refer to the code designations table below

- Pressure Settings: Class #150 / PN16: 4 – 16 bar (60 – 235 psi)

Class #300 / PN25: 7 – 25 bar (100 – 365 psi)

Maximum Differential for pump-relief valve or PSV:

25 bar/350 psi

Maximum Differential for PCV duty:

12 bar/175 psi

Pump relief sizing shall be in accordance with the NFPA 20 guidelines.

Elastomer

- HTNR - Fabric Reinforced High-Temperature Compound.

System Installation

A typical installation of the BERMAD model 43T features a pilot valve for the automatic and accurate maintenance of a constant preset maximum upstream pressure, regardless of fluctuating demand. The fast opening 43T reliably relieves excess system pressure to the sump or atmosphere, meeting NFPA, UL, and FM requirements for fire pump service. A unique actuator design ensures quick and smooth valve action.

Pressure reduction systems

- The fast response of the 43T preempts pressure-reducing valve reaction and

prevents

overpressure peak damage to sensitive equipment - Backup/redundancy for reducing valve to ensure pressure zone rating at all times

- Thermal relief: Relieves overpressure caused by changes in temperature.

Deeco - Bermad - FP-43T - Pressure Reduction System

Recommended Relief Valve Sizing for pressure-reducing systems

Deeco - Bermad - FP-43T - Relief Valve Sizing for Pressure Reducing Systems

Fire pump relief

- Pressure relief for individual diesel fire pumps, in accordance with the NFPA 20 guidelines

- Suitable for a vertical turbine and horizontal fire pumps

Deeco - Bermad - FP-43T - Fire Pump Relief

Technical Specifications

Engineering Specifications

The pressure relief valve shall maintain a constant, preset, maximum upstream pressure regardless of fluctuating demand, it shall be a UL-listed and FM-approved, 25 bar / 365 psi rated, line pressure driven and pilot operated, pressure control valve. The valve shall be of the elastomeric type with a straight-through Y-type body design. It shall have an unobstructed flow path, with no stem guide or supporting ribs. Valve actuation shall be accomplished by a single-piece, rolling diaphragm bonded with a rugged radial seal disc. The diaphragm assembly shall be the only moving part. Removing the valve cover for inspection and maintenance shall be in line with and shall not require the removal of the control trim. The control trim shall be supplied pre-assembled and hydraulically tested by a factory certified to ISO 9000 and 9001 standards.

Dimensions and Weights

Notes:

(1) Refers to the length dimensions for Raised Face ANSI #150, ISO 16 Flanged, Threaded and Grooved valves

(2) Refers to the length dimensions for Raised Face ANSI #300 and ISO 25 Flanged valves

(3) Leq (Equivalent Pipe Length) refers to a fully opened valve with turbulent flow in new steel pipe schedule 40, values are given for general consideration only

(4) Kv/Cv values given for a fully opened valve

(5) Exact dimensions for the trim envelope may vary with specific component positioning

Due to the wide range of options and criteria for correct model selection, pricing and configuration are available on application only.

Please contact us for more information.