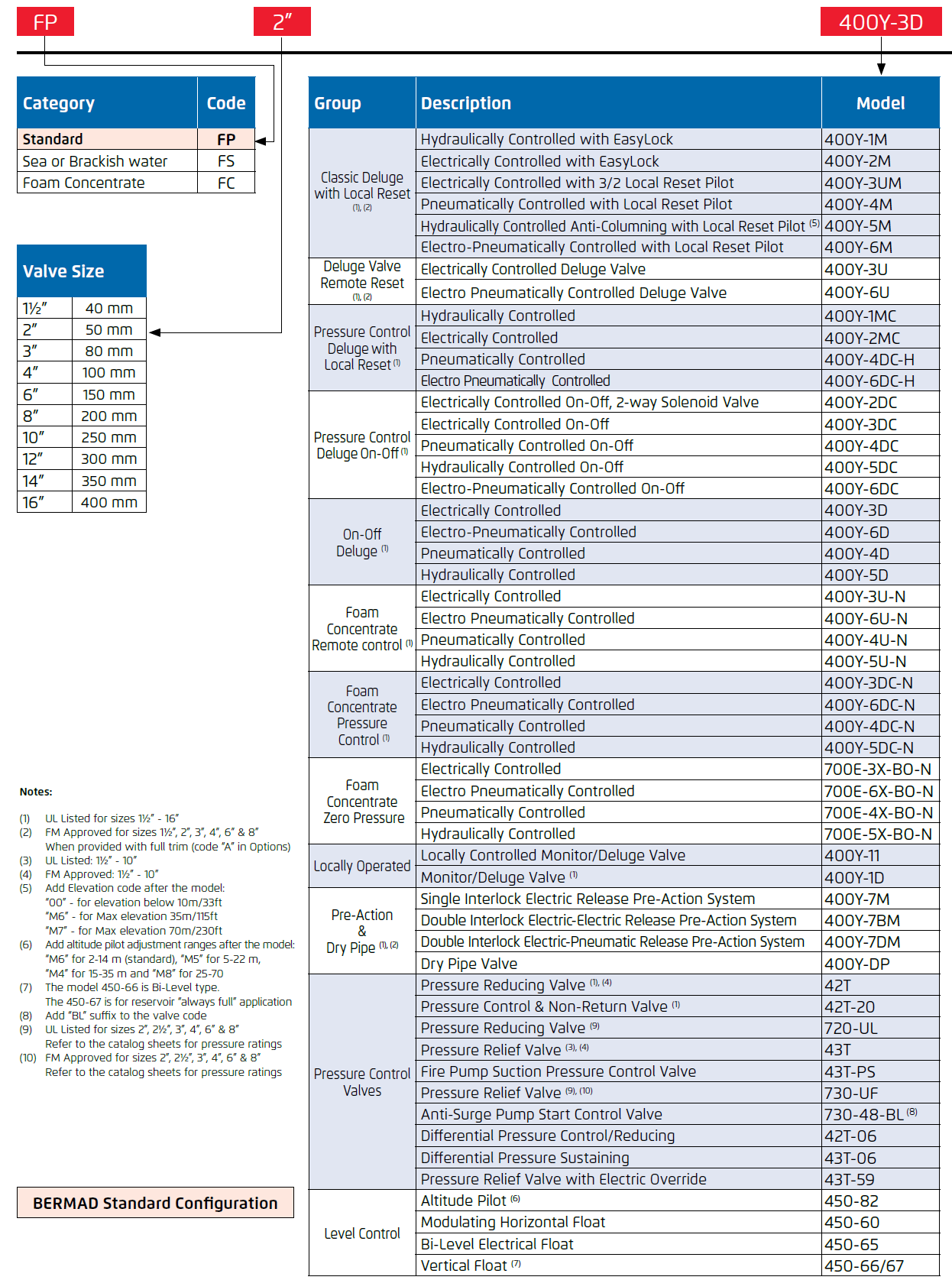

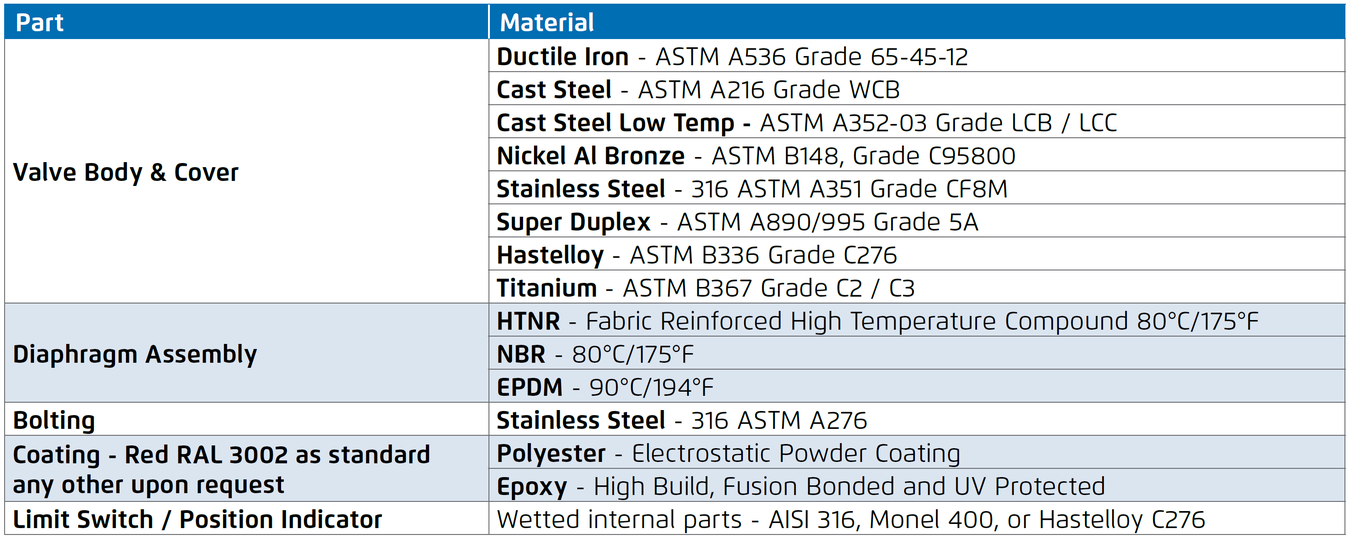

| Brand: | Bermad |

| Category: | Control Valves, Fire Protection Series |

| Size Range: | 40-400mm |

| Connection: | Flanged or Grooved |

Product Description

The BERMAD FP/FS-400Y Torrent valve has been designed specifically for the fire protection industry, with an emphasis on rugged reliability and high performance to comply with the most demanding standards.

The BERMAD 400Y is a straight-through, hydraulic, line pressure-driven, elastomeric, rolling diaphragm globe valve approved for 25 bar/365 psi with an industry-leading flow capability. It is equally suited for vertical or horizontal installation and is available in pipe diameter sizes from 1½” to 16” (DN40 to DN400).

The BERMAD 400Y is designed for flow control in deluge, pressure control deluge, remote on-off, monitor remote control, pre-action systems, pressure reduction and pressure relief. It is excellent for all fluids used in fire protection systems, from firewater supplies to foam solution, seawater, foam concentrate and other corrosive liquids. It can be manufactured from various materials and coatings to suit a wide range of specifications and hazardous locations. It is certified and approved to the latest fire protection standards.

The 400Y’s unique hydrodynamic straight-through Y-shaped design, with an unobstructed flow path, free from any supporting cage, in-line ribs, or shafts provides very high flow capabilities with minimal head/pressure loss. Providing resilient, drip-tight sealing, the internal design of the valve is based on innovative Vulcanized Radial Seal Disk technology (VRSD) that uses advanced rubber-based materials to achieve a solid, single-piece, elastomeric unit. This is composed of a flexible, fiber-reinforced diaphragm vulcanized with a rugged, radial seal disk. It is hydraulically balanced and peripherally supported to avoid tension and protect the elastomers, resulting in long life and dependable actuation, even under harsh conditions. Quick in-line inspection and servicing are enabled by a detachable valve cover. The elastomeric assembly can easily be removed without removing the valve from the line or removing the valve control trim.

Approvals

Refer to specific model data sheets for applicable standards

The BERMAD 400Y Torrent Deluge Valve is UL Listed and FM Approved when installed with specific components & accessories. Refer to the current UL and/or FM fire protection equipment directory or consult BERMAD for any component approval recently to appear in any equipment directory.

Exploded View

Bermad - FP400Y - Exploded View

Technical Data

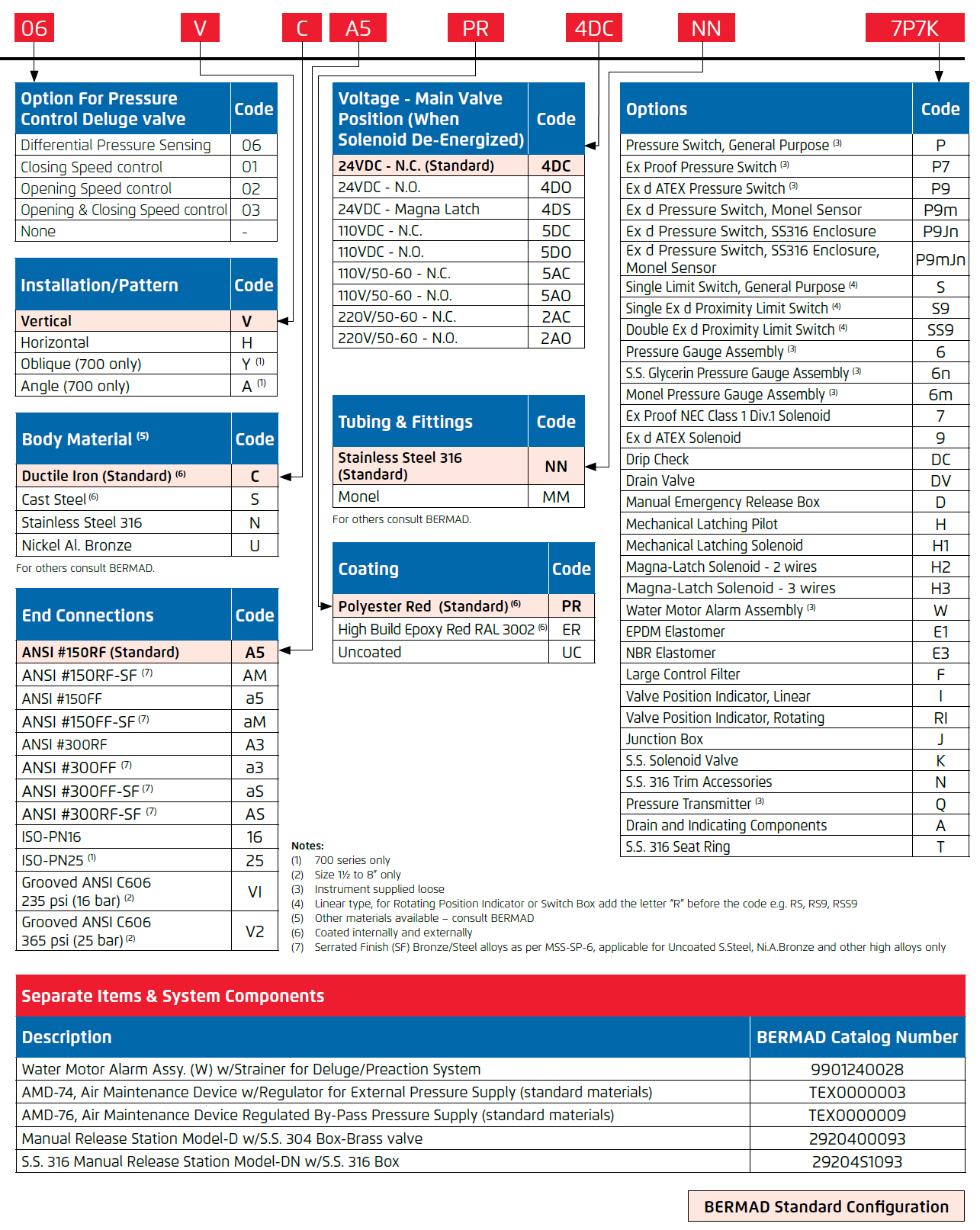

Operation

ON/OFF Operation

In the closed position (Fig 1a): The water pressure supplied through the priming line (2) is trapped in the control chamber (1) by the operating valve (3) pressing the seal disc (4) down and thereby sealing the valve and keeping the system piping dry. In the open position (Fig 1b): Pressure is released from the control chamber by way of the operating valve (3), which can be activated either electrically, hydraulically, pneumatically, or manually. With no pressure in the control chamber, the seal disc will open and allow an unrestricted water flow through the valve into to the system piping.

Pressure Control

The BERMAD 400Y Torrent valve is highly suitable for pressure regulation in fire protection applications either for Pressure Reduction - Model 42T or for Pressure Relief - Model 43T. The BERMAD Model 42T reduces water pressure automatically and accurately from a higher inlet pressure value to a lower set outlet value. It operates under both flow (Fig 2b) and non-flow (static) conditions (Fig 2a). The pressure-reducing pilot valve [3] senses changes in outlet pressure and modulates pressure in the main valve control chamber [1] to maintain the set outlet pressure. When outlet pressure rises above the set pressure: The pilot valve throttles causing water pressure to accumulate in the control chamber (1) by way of the restriction orifice (2). This forces the main valve to close further and reduce outlet pressure. When outlet pressure drops or falls below the set pressure: The pilot valve opens wider than the passage presented by the restriction orifice, enabling more water to exit the valve control chamber via the pilot than can enter by way of the restriction orifice, releasing pressure from the control chamber. This causes the main valve to open and maintain the set pressure. The restriction orifice also determines the valve’s closing speed. For valves 8” and larger an adjustable needle valve is provided.

Deluge Valve

The BERMAD 400Y is available in a wide variety of deluge configurations, controlled electrically, hydraulically pneumatically or electro-pneumatically, pre-action, and dry pipe. See below the principle of operation for the Electrically Controlled Deluge Valve with Manual Reset -model 400Y3UM

The BERMAD 400Y is held closed by water pressure in the control chamber [1]. Upon release of pressure from the control chamber, the valve opens. Under NORMAL conditions, water pressure is supplied to the control chamber via the priming line [2] and the priming orifice [5]. It is then trapped in the control chamber by a check valve [4] and a relay valve (URV-M) [7] that is held in the supply position by hydraulic pressure supplied through a three-way solenoid valve [8]. Under FIRE conditions, water pressure is released from the control chamber, either with the manual emergency release [6] or by the URV-M switching to the release position in response to the solenoid valve being activated. This latches the 400Y deluge valve open, allowing water to flow into the system piping.

Combined - Deluge/Pressure Control

The BERMAD 400Y Pressure Control Deluge models are for use with high-pressure water supplies or for varied pressure control requirements. These models are fitted with a pressure-reducing pilot (1) fig 3a, integrated into the trim. This enables the dual function of a deluge valve whilst simultaneously reducing a higher upstream pressure to a lower and stable downstream pressure. See below the operation drawing for the Pneumatic Pressure Control On-Off Deluge Valve model 400Y 4DC, figures 3a & 3b.

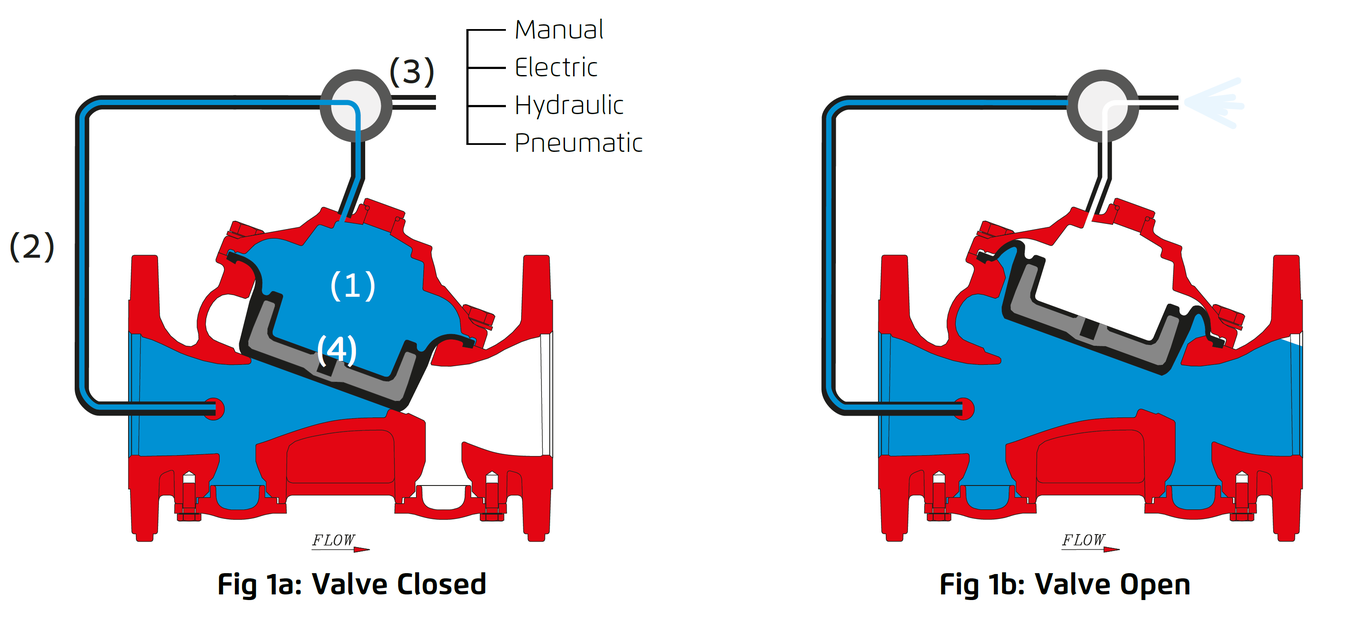

Construction Materials

The BERMAD 400Y valve is available in a variety of materials and high alloys to ensure optimal suitability for a wide range of applications. To enable a higher corrosion resistance for ductile iron or steel valves a UV-protected fusion bonded high-build epoxy coating is optional.

Materials

Bermad - FP400Y - Materials

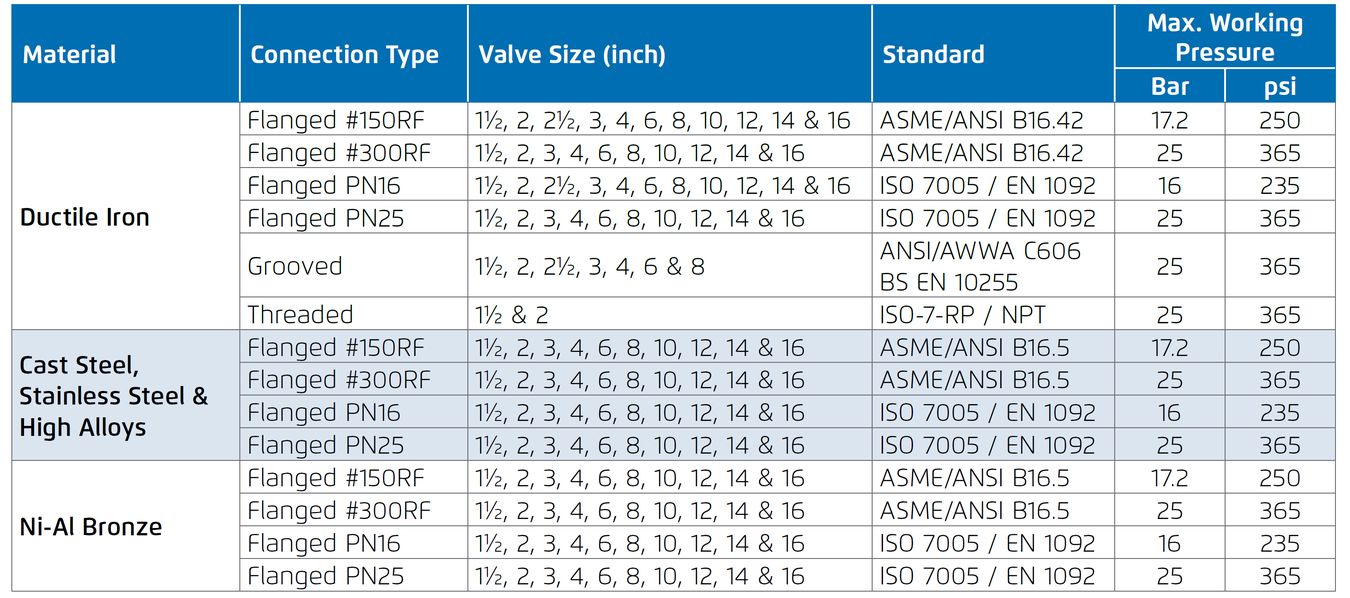

Connection Type / Pressure Rating

Notes:

1. Standard flange facing: Raised Face (RF), serrated finish Flat Face (FF) available on request.

2. For any other material options/requests, contact BERMAD.

3. For specific WP ratings Refer to ASME/ANSI B16.4/B16.5 for other temp/pressure levels

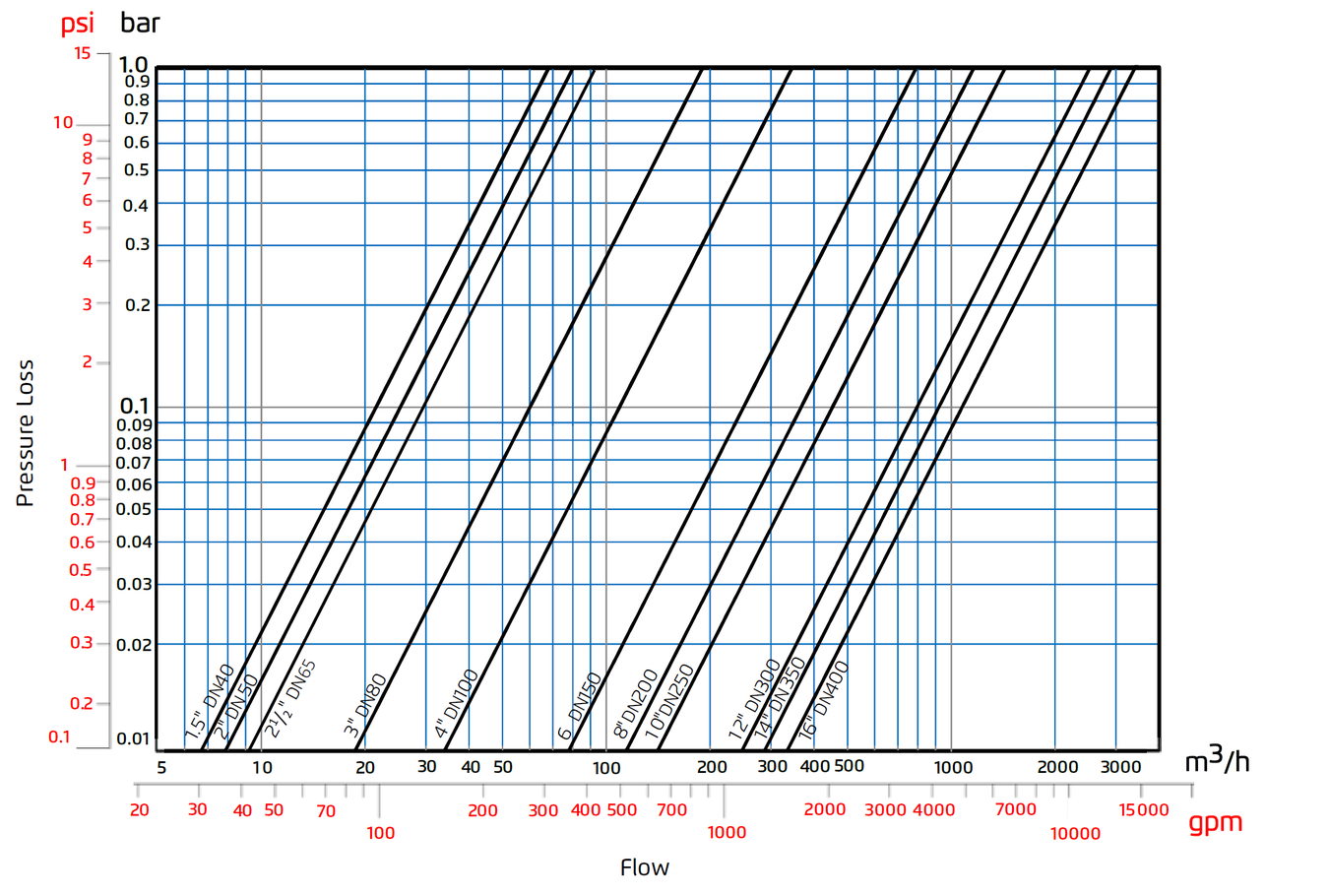

Flow Chart

Bermad - FP400Y - Flow Chart

Flow Properties

Note:

(1) Leq: Equivalent pipe length for turbulent flow in clean commercial steel pipe schedule 40 (Leq values given are for general consideration only. Actual Leq may vary somewhat with different pipe manufacturers)

Cv = 1.155 Kv

To calculate pressure loss across the valve (fully opened), use this formula

∆p = SG (Q/Kv)²

∆p = Differential pressure across the valve (bar: psi)

Kv = Valve flow coefficient (flow in m³/h at 1 bar diff press) – see table above

Cv = Valve flow coefficient (flow in gpm at 1 psi diff press) – see table above

Q = Flow rate (m³/h; gpm)

SG = Specific gravity of medium (water = 1.0)

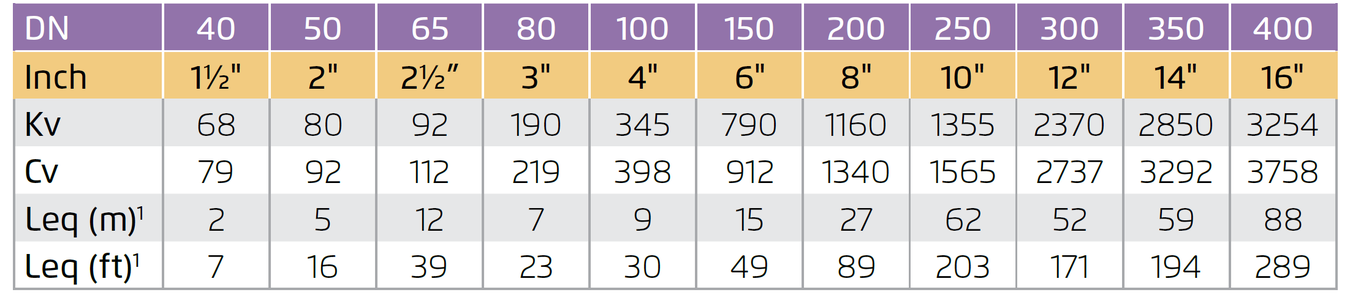

400Y Pressure Control Deluge or Pressure Reducing Valve Pressure Drop

Use this graph for pressure control valves, whether pressure control deluge or dedicated pressure reducing, to determine pressure loss when water supply pressure falls below the valve set pressure.

Bermad - FP400Y - 400Y Pressure Control Deluge or Pressure Reducing Valve Pressure Drop

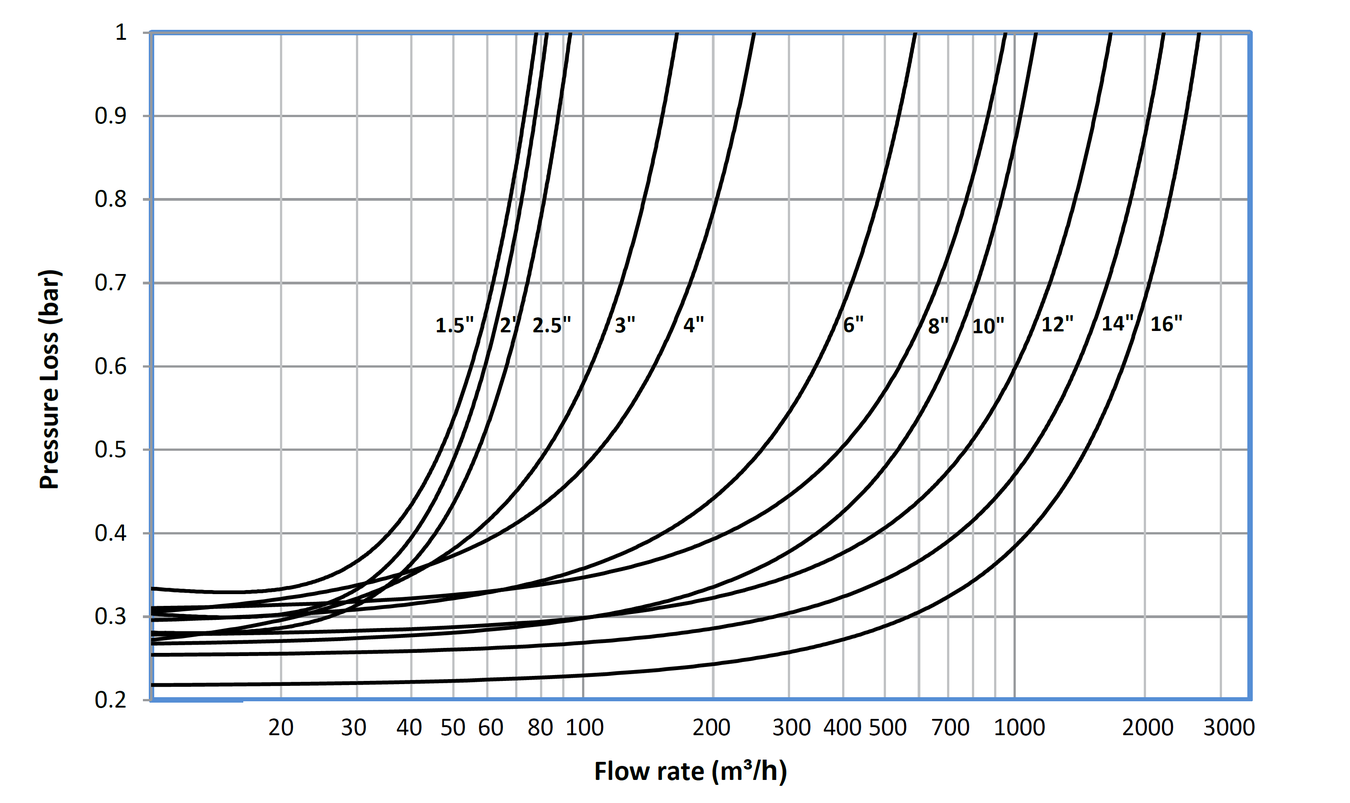

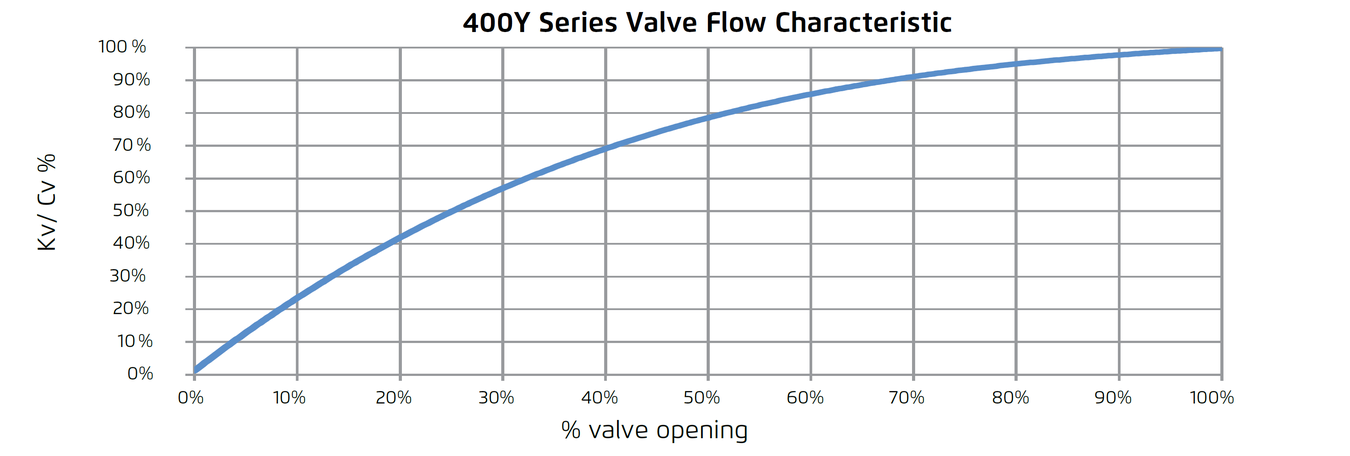

400Y Torrent Valve Flow Characteristic

The relationship between control valve capacity and valve closure travel is known as the “Flow Characteristic” of the Control Valve. With a flat closure disc and linear travel the Torrent 400Y valve has been designed for quick opening. In the below grap,h we can see that at only 50% opening of the valve it has already reached 80% of its flow capacity or Kv/Cv. This quick opening characteristic is highly desirable in fire protection and enables an accelerated response to a fire event, saving precious seconds at the initiation of a fire extinguishing / suppression operation ,

Bermad - FP400Y - 400Y Series Valve Flow Characteristics

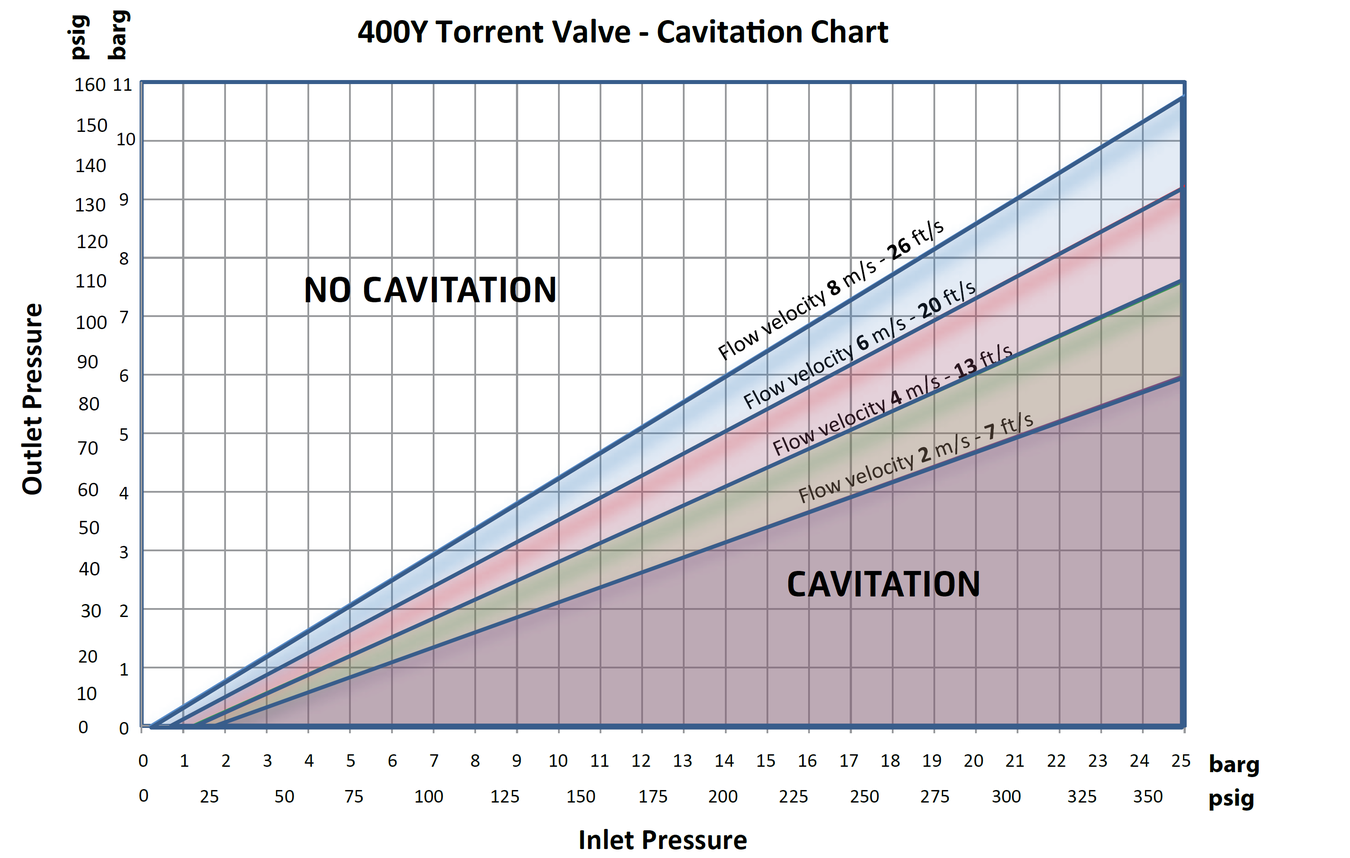

Cavitation Considerations for Torrent Pressure Control Valves

Cavitation is a phenomenon that occurs in all valves at varying degrees of “harsh” flow/pressure conditions. In some cases, it may damage the valve and piping by the effects of erosion and vibration. Cavitation also generates noise and may limit and ultimately choke the flow. As the pressure differential across the valve increases, the static pressure of the flow passing through the throttling area of the valve (the Vena Contracts) drops sharply. When the fluid’s static pressure reaches liquid vapor pressure, vapor cavities (bubbles) form and grow until they violently implode by the recovered pressure downstream of the valve seat. The implosion of these cavities generates high-pressure, surges, micro jets, and intense heat, which can erode valve components and downstream piping. In its final stage, cavitation flashes and chokes the flow.

Using the Cavitation Chart

The below chart is applicable to all 400Y pressure control valves, whether deluge pressure control or dedicated pressure control in typical fire protection applications with intermittent use. The chart should be used only as a guide to assist in determining the correct pressure differentials as a function of flow and vice versa. After selecting the valve size, establish the maximum pipe flow velocity, the inlet pressure and the outlet pressure. If the intersection point of the inlet and outlet pressure falls within the shaded area below the relevant flow velocity line, cavitation may occur. The severity and likelihood of the cavitation will increase the lower the point is below the velocity line. WARNING: Extended use at a regulation point that falls within the shaded area can cause extensive damage to the valve body and internals

Bermad - FP400Y - 400Y Torrent Valve- Cavitation Chart

Avoiding Cavitation Damage

A) Specify a larger valve

B) Consider using a cavitation-resistant material

C) Reduce system pressure in stages to distribute the hydraulic load. Design each valve to reduce to a differential pressure that is not subject to cavitation

If none of the above provides a viable solution consult Deeco.

Technical Specifications

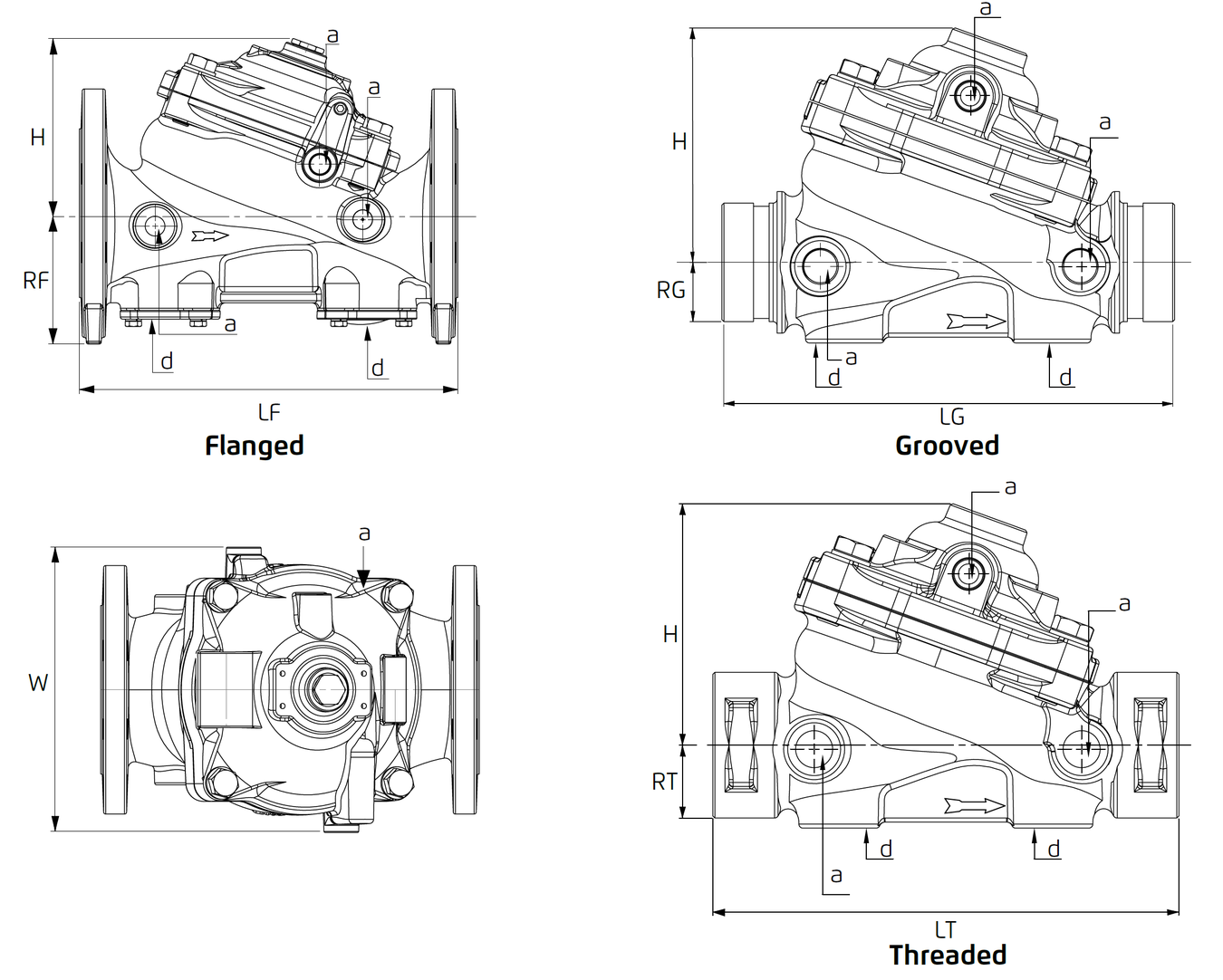

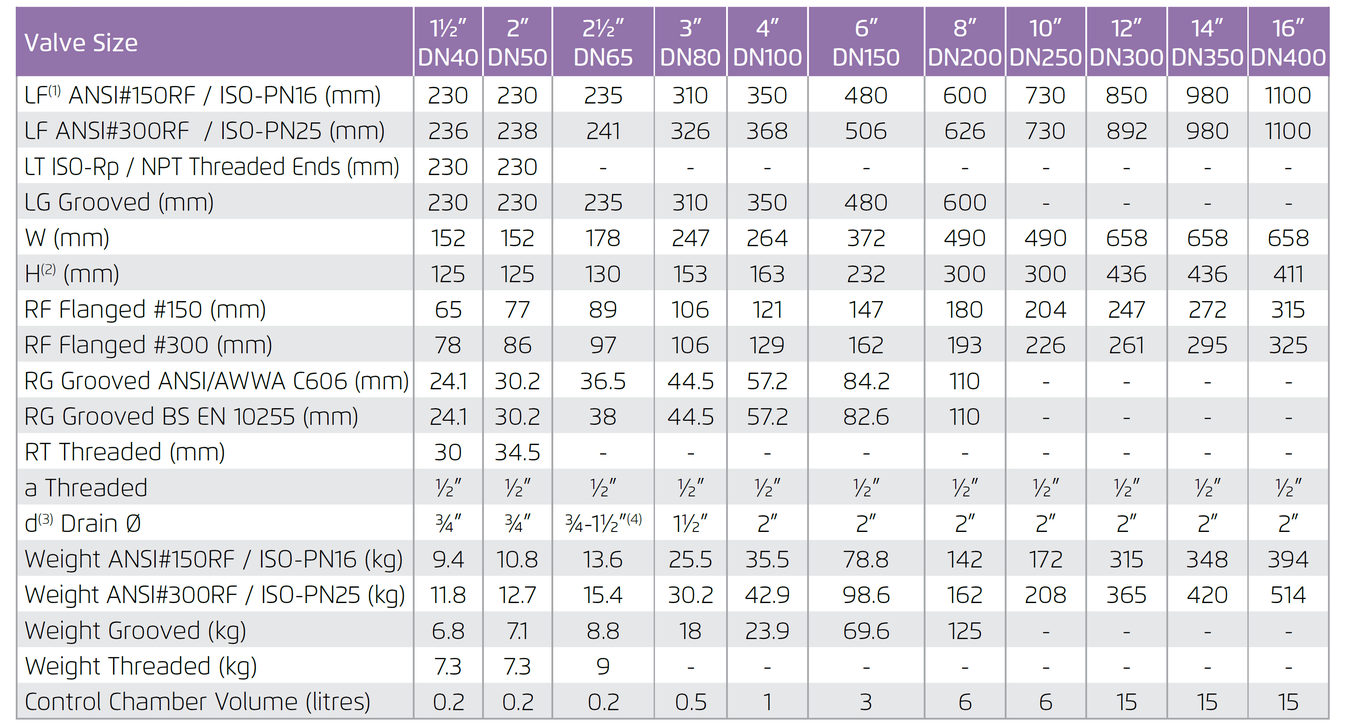

Dimensions and Weights

(1) Standard flange facing: Raised Face (RF). Flat Face (FF) flanges available on request

(2) Add 45 mm when using the position indicator, and 120mm for the enclosed limit switch

(3) 1½” and 2” valves drain ports are threaded. 3” and valves larger are provided with 3-bolts flange connections

(4) Upstream drain valve 1½” downstream drain valve ¾”

Additional Valve Options and Features

Factory Fitted Options

- Local valve position indicator beacon:

The valve can be equipped with a protective-covered, dual-color, quarter-turn position indicator, readable from a distance of 50 meters.

- Valve Limit Switches and position monitoring device:

A limit switch unit with dual SPDT limit switches is enclosed in a protective switch box that can interface for monitoring any Fire & Gas control system. The switch box incorporates a dual-color visual position indicator

- Swivel Drain Valve unit:

The 360-degree swivel ability of the drain valve connections facilitates installation in confined spaces.

- Seat Insert:

The seat insert option is designed for applications where there is a high potential for cavitation damage. Specify this option for pressure control applications having high-pressure differentials.

- Seawater Resistance:

The valve body and cover can be cast in various alloys to provide the required resistance to a corrosive internal fluid, such as seawater, or to a corrosive external environment, as with offshore applications or coastal environments. Coating ductile iron or steel valves with high-build fusion bonded epoxy with UV protection can also provide corrosion resistance.

Position Indicator and Limit Switch

Indicator Beacon

For on-site visual confirmation of the valve's status, the protective-covered, dual color quarter turn position indicator beacon is readable from at least 50 meters / 150 ft The indicator’s rugged Lexan™ construction makes it highly resistant to impact damage and tolerant to most corrosive environments

Model SS9J Linear Proximity Limit Switch

The Model SS9J Linear Proximity Limit Switch is a device for monitoring the position status of BERMAD control valves. It is equipped with two hermetically sealed proximity sensors, enabling. remote signaling upon the opening and/or closing of the valve The model SS9J is suited for use in hazardous locations, harsh environments and corrosive media, and is designed with an integral 316 stainless steel junction box enclosure

Model QT Rotary Limit Switch

The Rotating Limit Switch Box Assembly model QT is an accessory that enables remote and local valve position monitoring of BERMAD 400Y Torrent Deluge / Water Control Valves. The low profile robust anodized and epoxy-coated aluminum housing makes it well-suited for use in corrosive, heavy wash-down applications and harsh environments. The switch box incorporates a highly visible dual-color visual position indicator

Due to the wide range of options and criteria for correct model selection, pricing and configuration are available on application only.

Please contact us for more information.