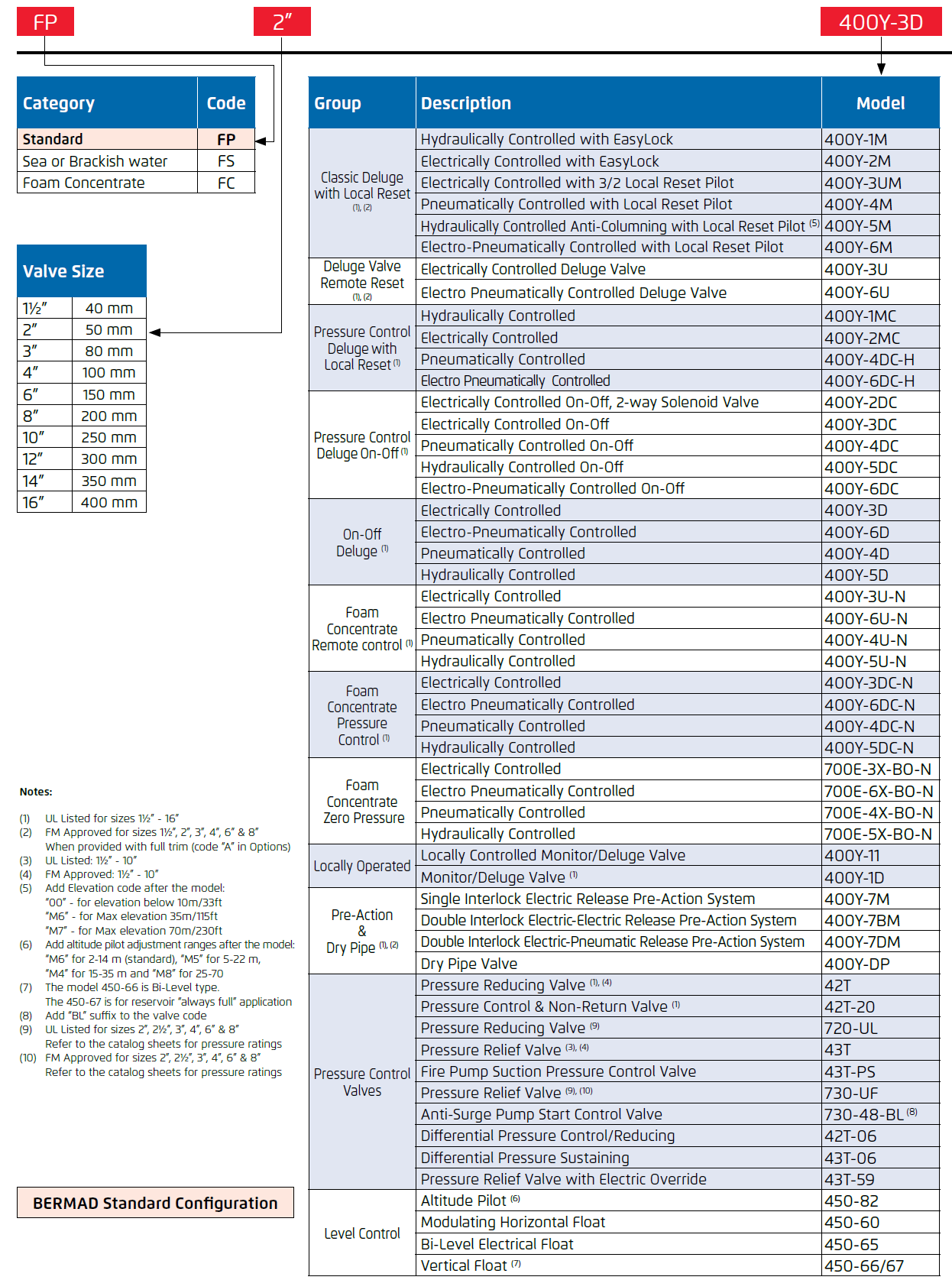

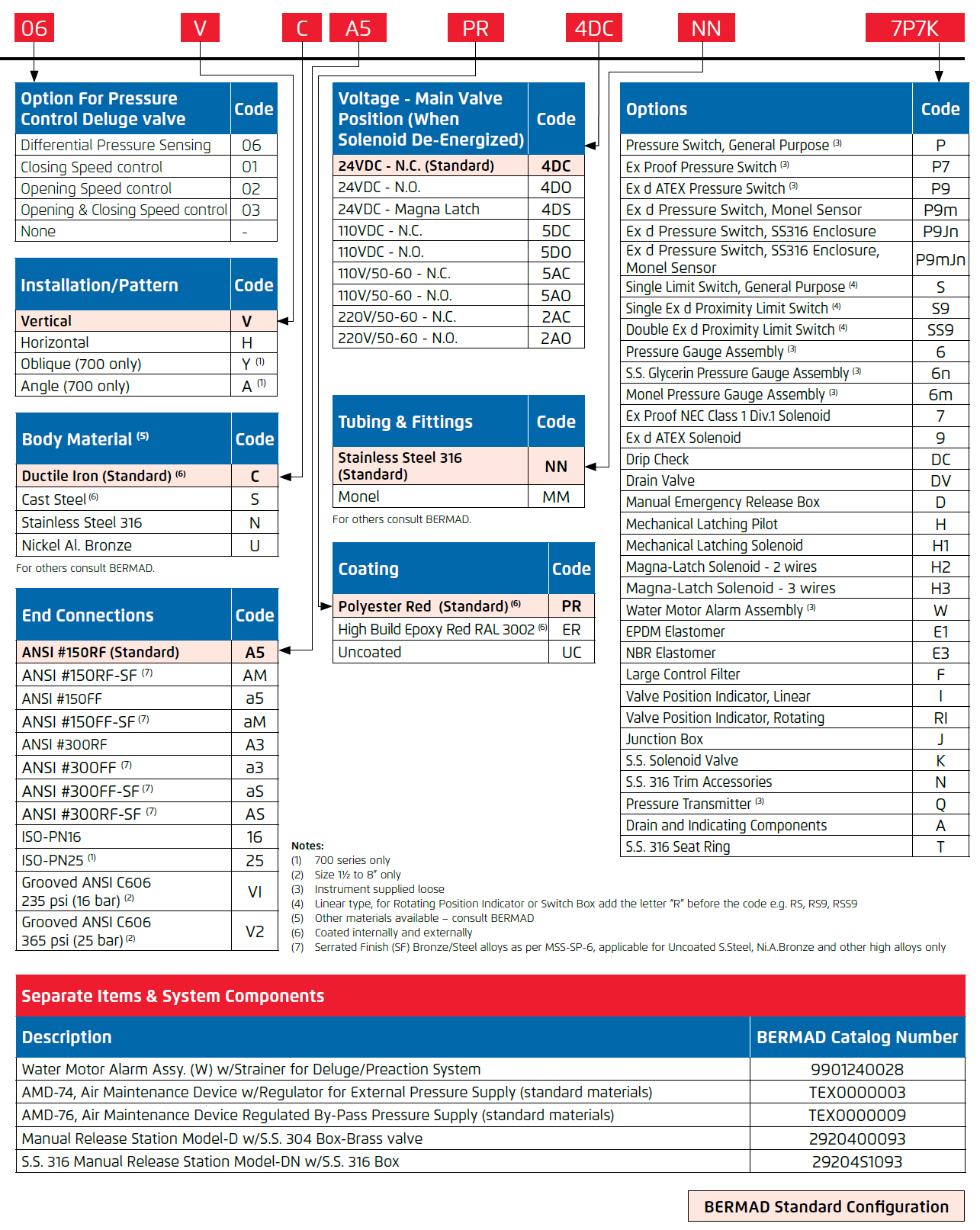

| Brand: | Bermad |

| Category: | Control Valves, Fire Protection Series |

| Size Range: | 40-400mm |

| Connection: | 40-400mm - Flanged |

| Engineering Data: |

Product Description

The BERMAD model 400Y-5DC is an elastomeric, hydraulic line pressure-operated deluge valve, designed specifically for advanced fire protection systems and the latest industry standards. The 400Y-5DC is activated by a hydraulically operated relay valve, through which the opening and closing of the valve can be controlled either with a remote hydraulic command or with a wet pilot line with closed fusible plugs. An integral pressure-reducing pilot valve ensures a precise, stable, pre-set downstream water pressure. The optional valve position indicator can include a limit switch suitable for Fire & Gas monitoring systems. The 400Y-5DC is ideal for systems that combine a remote wet pilot line with a high-pressure water supply.

Features and Benefits

- Safety and reliability

- Time-proven, simple, fail-safe actuation

- Single-piece, rugged, elastomeric diaphragm seal VRSD technology

- An Obstacle-free, uninterrupted flow path

- No mechanical moving parts

- Ensures precise, stable downstream water pressure

- Valve position limit switches (optional)

- High performance

- Very high flow efficiency

- Straight-through Y-type body

- Approved for PN25/365psi

- Specifically-designed for fire protection

- Face-to-face length standardized to ISO 5752, EN 558-1

- Meets industry standards requirements

- Quick and easy maintenance

- In-line serviceable

- Fast and easy cover removal

- Swivel-mounted drain valves*

* from 3” valves and larger

Approvals

Additional Features

- Valve position limit switches

- Alarm pressure switch

- Sea water compatibility

- Drain valve/s inlet/outlet

- For “automatic activation” select BERMAD local or remote reset model

Typical Applications

- Remote control water spray systems

- Remote hydraulic control

- Foam applications

- High / Fluctuating water pressure supply

Technical Data

Operation

The BERMAD model 400Y-5DC is held closed by water pressure in the control chamber [1]. Upon release of pressure from the control chamber, the valve opens. Under NORMAL conditions, water pressure is supplied to the control chamber via the priming line [2] strainer [3] and a restricted orifice [5] it is then trapped in the control chamber by a check valve [4], manual emergency release [6], and a hydraulic relay valve (HRV) [7] that is held closed by hydraulic pilot line pressure [E]. The water pressure trapped in the control chamber holds the main valve diaphragm against the valve seat, sealing it drip-tight and keeping the system pipes dry. Under FIRE conditions, water pressure is released from the control chamber, either with the manual emergency release or by the HRV opening in response to a decrease in hydraulic pressure from a pilot line or a remote release [E]. This opens the 400Y-5DC deluge valve, allowing water to flow into the system piping and to the alarm device/s [9]. The pressure reducing pilot valve [8] modulates the main valve to maintain the set downstream pressure. When outlet pressure changes, the pressure-reducing pilot opens or closes in response. This regulates the pressure in the main valve’s control chamber, thus modulating the position of the diaphragm seal disk to maintain the set downstream pressure.

System P&ID

Components

1 BERMAD 400Y Deluge Valve

2 Priming Ball Valve

3 Priming Strainer

4 Check valve

5 Restriction Orifice

6 Manual Emergency Release

7 HRV-Hydraulic Relay Valve

8 Pressure Reducing Pilot Valve

Optional System Items

PI Pressure Gauge

I Valve Position Indicator

DC Drip Check

AV 3-Way Alarm Valve

DV Drain Valve

PS Pressure Switch

ZS Limit Switch Assembly

W Water Motor Alarm

Main Valve

Available Sizes and Connection

- 40-400mm - Flanged

- 40-200mm - Grooved

Pressure Rating

- ANSI#150 - 16 bar / 235 psi

- ANSI#300 - 1½” to 10” 25 bar / 365 psi

12” to 16” 20 bar / 300 psi - Grooved - 25 bar / 365 psi

- Threaded – 25 bar / 365 psi

- Setting range: 4 - 12 bar (60 - 175 psi)

for other settings ranges consult Deeco.

Elastomer

- HTNR - Fabric Reinforced High-Temperature Compound

System Installation

A typical installation of the BERMAD model 400Y-5DC features actuation via a pressure operated relay valve. This relay valve can be operated to actuate the main valve by using either a remote hydraulic pressure supply or a wet pilot line with fusible plugs. A pressure reducing pilot valve within the control trim ensures a precise and stable preset downstream water pressure. When fitted with a limit switch the valve can send a feedback signal to a remote valve position monitoring system.

Deeco - Bermad - FP-400Y-5DC - Sysytem Installation

Technical Specifications

Suggested Specifications:

The deluge valve shall be UL listed, 25 bar/365 psi rated, elastomeric-type, with a straight-through, Y-type body. The valve shall have an unobstructed flow path, with no stem guide or supporting ribs. Valve actuation shall be accomplished by a single-piece rolling diaphragm, bonded with a rugged radial seal disk. The diaphragm assembly shall be the only moving part. The deluge valve shall include a pressure-reducing pilot a Y-type strainer, a ball drain valve, an automatic drip-check with manual override, 4-inch pressure gauges and a manual emergency release housed in a stainless steel box. The valve drain socket shall be flanged and have a 360-degree swivel. The valve shall be equipped with two limit switches. Removing the valve cover for inspection and maintenance shall be in line with and not require the removal of the control trim. The deluge valve and its entire control trim shall be supplied pre-assembled and hydraulically tested by a factory certified to ISO 9000 and 9001 standards.

Dimensions and Weights

Notes:

(1) Refers to the length dimensions for Raised Face ANSI #150, ISO 16 Flanged, Threaded and Grooved valves

(2) Refers to the length dimensions for Raised Face ANSI #300 and ISO 25 Flanged valves

(3) Flow coefficients apply to a fully opened valve

(4) Leq (Equivalent Pipe Length) refers to turbulent flow in new steel pipe schedule 40 for a fully opened valve, values given for general consideration only

(5) IMPORTANT: Dimensions for the trim envelope or may vary with specific component positioning and where needed can be arranged to suit specific requirements - allow a tolerance of at least ±10%.

Due to the wide range of options and criteria for correct model selection, pricing and configuration are available on application only.

Please contact us for more information.