| Brand: | Bermad |

| Category: | Metering, Electromagnetic Water Meters |

| Size Range: | 50-100mm |

| Connection: | Grooved |

| Performance: | OIML R49:R400 |

Product Description

M10 is an electromagnetic flow meter grooved sensor that covers all diameters from DN50 to DN100. When high accuracy, lightweight, and compact dimensions are required, the choice of sensors cannot be other than M10.

These performances allow us to measure low flow rates precisely and repeatably, even in difficult/ problematic applications with solid parts.

The M10 sensor series bases its operation on the Faraday Principle, by which a conductor crossing a magnetic field generates an electrical potential perpendicular to the field itself. On the top and the lower side of the composite flow tube, two coils are installed; the magnetic field generated by the electric current crossing the coils induces in the electrodes a potential difference proportional to the flow rate.

The integrated battery-powered converter generates the current supplying the coils, acquires the electrode's potential difference, processes the signal to calculate the flow rate, and manages all communications.

The entire sensor has an IP68 protection degree suitable for permanent immersion in water up to a depth of 1.5m.

A Revolutionary Perspective of the Flow Metering

The M10 is a battery-powered and 12VDC electromagnetic flow meter for use in agriculture, irrigation, district metering areas (DMA), water abstraction, custody transfer measurement of potable water (MI-001, OIML R49), and many other applications. Unlike other water meters, the M10 is a maintenance-free meter, offering a much wider range of flow, in a compact version. Thanks to the optimized flow profile, the M10 can be installed virtually anywhere without straight inlet or outlet runs, behind pipe bends, slide valves, or a reduction in the pipe. Its measuring tube is specifically designed to enable a stable measurement even at the lowest flow rates.

Made out of highly reinforced polyamide, the meter is the perfect solution for leak detection and pressure management systems. The highly robust and lightweight structure allows IP68 installations by the manufacturer's guidelines.

Victualic OGS process connections make the flow meter compatible with almost all installations, and adapting flanges of all types and standards are also available. Easy and quick to install, users will find this flow meter the perfect solution compared not only to mechanical meters but to any other non-moving parts flowmeters.

The inbuilt logger functionality provides total flexibility - enabling data to be interrogated in precise detail through the smart and user-friendly Mag-Net app, available on Apple and Google Play Store.

Features and Benefits

- Long-lasting performance: Battery powered for up to 10 years or 12VDC

- U0-D0: Zero upstream and downstream distances (MID-001 OIML R49 certified)

- All-in-one: Electronic converter integrated into the sensor body, compact and lightweight for easy use

- Highly resistant: Reinforced polyamide with Victaulc OGS process connections

- Empty pipe detection: Empty pipe detection on measuring electrodes

- Easy management, easy programming: Mag-Net app available on App Store and Google Play.

- Data logging: Data is automatically stored in the internal EEPROM memory. Up to 100,000 lines of active data logging.

- No moving parts

- Grooved connection - fits all applications

- Long-lasting stability and precision, no filter needed, zero maintenance

- Lightweight sturdy structure

- Accurate measure at high flow rates and low flow rates

- Bi-directional measure

- Internal parts are protected by a bi-component resin to increase protection from external agents

- A wider range of measurement

Typical Applications

- Irrigation

- District metering of potable water

- Distribution

- Leak detection and monitoring

- Installation of small places without straight distances

- Fiscal measures, custody transfer

- Applications with very low / high flow rate

The M10 internal part of the sensor allows an optimized and accelerated flow profile which permits to install the sensor in any kind of condition; no need to have straight sections/segments of pipes upstream and downstream. This U0-D0 condition enables to have extreme flexibility in the flow meter installation position.

Easy and Intuitive Interface

Everything you need from flowmeter with a blink of an App. In a fast-developing and interconnected world, data must be available and exchanged anytime, anywhere. Mag-Net app is the Bermad solution.

- Reliable

Ultra-low power Bluetooth communication - Contactless

A contactless interface allows users to interact with the transmitter up to a range of more than 10m from the comfort of their car. - Chart and retrieve data

The Mag-Net app allows users to view the log file on their smartphone/tablet and download it as a CSV file. - Infinite possibilities

Consult, analyze, and monitor, the data directly with your touch through simple gestures - Easy and Intuitive

The Mag-Net app is easy and intuitive to use, allowing users to deal with the instrumentation. - Smart configuration

Users can easily configure or modify settings of their flow meters using Mag-Net app.

Standards Reference

The M10 electromagnetic meters are marked CE and are manufactured according to the following standards:

- 2014/53/EU

- 2014/30/EU - EN 61326-1:2013 (EMC)

- 2014/65/EU

- EN IEC 60529

- OIML R49-1:2013

- European directive 2014/32/EU (MID)

Technical Data

Structure: Integral Flowmeter

DN Range: 50-150mm

Nominal Pressure: 16 bar

Process Connection: Victaulic OGS

Fluid Conductivity: > 20 μS/cm

Process Temperature Range: 0 ÷ 80 °C

Materials in contact with water:

Flow tube: Glass fiber-reinforced plastic

Electrodes: AISI316L

Power Supply:

Battery Powered: 3.6 V Lithium Battery

Mains Powered: 12VDC (10.8 - 13.2V), max 100mA

Consumption: 0,25W-1W (Mains powered)

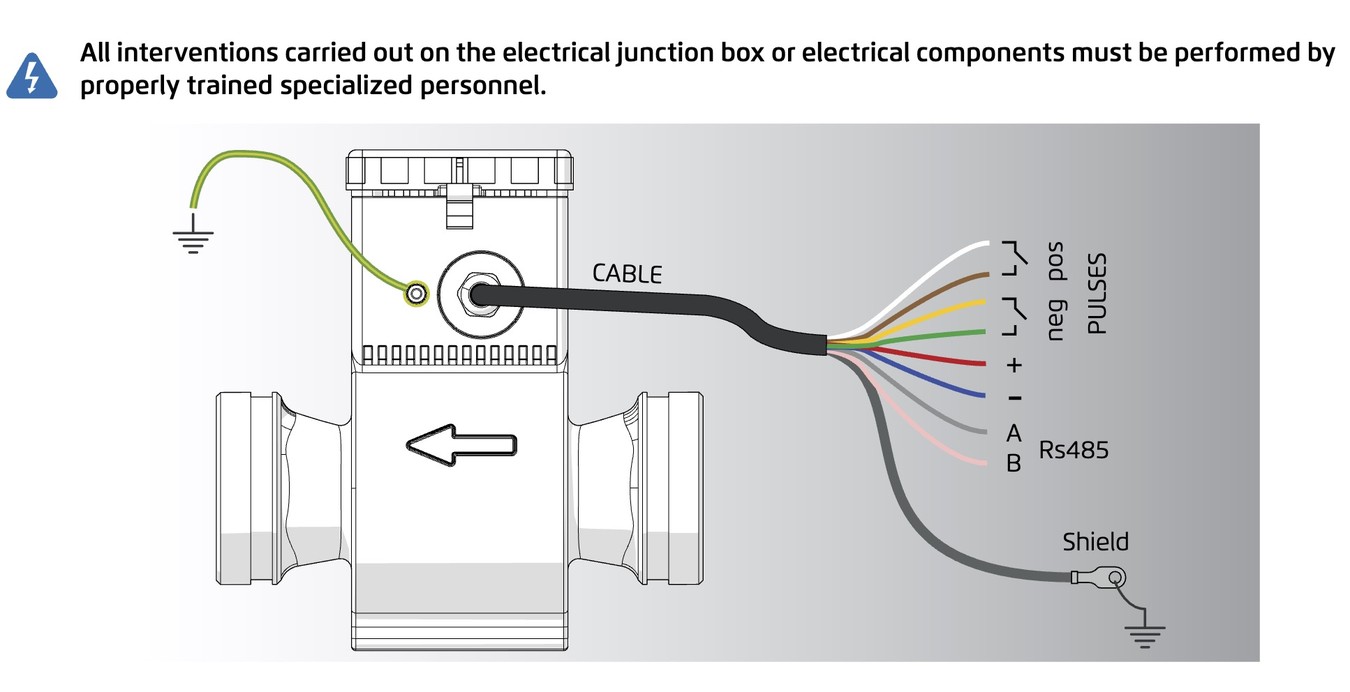

Outputs: 2 passive outputs (1 programmable), SSR Type (dry contact), galvanically insulated Max. Load +/- 35VDC, 100 mA protected against short circuits, minimum pulse duration 5ms. RS458 2 wire /half-duplex

Communication:

Modbus RTU Slave

Bluetooth

Display: LCD Segment display, with dedicated status icons, 8+6 digits

User Interfaces:

Magnetic reed

Bluetooth Mobile App

Euromag Link Software

Process memory:

100,000 data lines

Programmable frequency 1 - 120 minutes (15 minutes factory standard)

Metrological certificate: OIML R49-1:2013 / MID 2014/32/EU - Class 2 (if requested)

Temperature range:

Ambient: -20 - 60 °C

Process: 0 - 80 °C

Storage: -40 - 70 °C

Technical units: m, m3, l, ML, ft3, gal

Totalizers: 5 (2 Positive, 2 Negative, 1 Net)

Alarms and status icons: Status icons are displayed, and alarms recorded in the data logger

Self-diagnostic:

Excitation failure

Excessive ambient temperature

Wet electronic board

Low battery level / Mains voltage out of range

Pulses overlapping

Bluetooth communication error

Empty pipe

Measurement error

Software/memory malfunction

Mains power interruption

Software for communication and programming:

Bluetooth Mobile App - Mag-Net

Euromag Link Software (through Bluetooth dongle or RS485 interface)

Data Protection:

Customizable password protection

EEPROM Memory with safe data storage management

Body and Flanges

The M10 has a flow tube made from composite material. It is equipped with an integrated converter. The degree of protection is IP68. It may be installed between flanges up to PN 16 or ANSI 150. The sensor is grooved and can easily fit into all types of end connections with the preferred adaptor.

Internal Lining

The sensor body is in composite, thus the temperature of the liquid to be measured has to be between 0°C and + 80°C.

Electrodes and Grounding

The M10 has three electrodes in AISI 316L and, on request, they can be supplied in other materials. It should be noted that if the sensor is installed in metal pipe line, the liquid grounding does not require the use of grounding rings, because of the presence of the third electrode.

Calibration and Maximum Error

Each sensor is calibrated on a hydraulic test rig equipped with a ISO17025 traceable weighing system. The accuracy is equal to 0.2% ± 2mm/s. The repeatability of the measure is about 0.1%. Bi-directional measure. On request, the M10 can be supplied with certified MID OIML R49 for custody transfer.

Flow Rates Chart

Maximum Permissible Error is within the limits indicated in the following graph:

Dimensions

Bermad - Model M10 - Light Weight Electromagnetic Flow Meter

Battery Powered Electromagnetic Irrigation Flow Meter, PN16 Rated. OIML R49:R400

Bermad - M10050-VI

Bermad - M10050-FF

| Product Code | Size | Pressure Rating | Description |

|---|---|---|---|

M10050-FF |

50mm |

PN16 |

Bermad M10 Mag Meter, PN16, HP battery fitted, with 2m output cable - Flanged W/grounding rings |

M10050-VI |

50mm |

PN16 |

Bermad M10 Mag Meter, PN16, HP battery fitted, with 2m output cable - Grooved W/grounding rings |

M10080-FF |

80mm |

PN16 |

Bermad M10 Mag Meter, PN16, HP battery fitted, with 2m output cable - Flanged W/grounding rings |

M10080-VI |

80mm |

PN16 |

Bermad M10 Mag Meter, PN16, HP battery fitted, with 2m output cable - Grooved W/grounding rings |

M10100-FF |

100mm |

PN16 |

Bermad M10 Mag Meter, PN16, HP battery fitted, with 2m output cable - Flanged W/grounding rings |

M10100-VI |

100mm |

PN16 |

Bermad M10 Mag Meter, PN16, HP battery fitted, with 2m output cable - Grooved W/grounding rings |

Accessories

| Product Code | Size | Description |

|---|---|---|

M10-BATTERY |

All |

Bermad M10 Mag Meter - Battery High Performance |

M10-TECHCABLE |

All |

Bermad M10 Mag Meter - Technician Cable |