| Brand: | Vent-O-Mat |

| Category: | Air Valves, Combination Air Valves |

| Size Range: | 25 - 200mm |

| Connection: | 25-50mm - Threaded Male BSPT |

Product Description

The Vent-O-Mat Series RBX "Anti-Shock" air release and vacuum break valve, is the product of extensive research into the development of an efficient, but cost-effective solution to surge problems (both mass liquid oscillation and elastic transient phenomena) associated with any operating pipeline. Automatic dampening, relevant to the pipeline's needs is provided by either one of three design features. These special features are unique in a pipeline component of such compact and economical design.

Vent O Mat RBX Air Valve installed in Silverstream, New Zealand

Features & Benefits

- High-capacity air discharge during pipeline filling

- High volume air intake for vacuum break purposes, both during draining of water pipelines and/or column separations

- Independent third-party tested

- Controlled pressurized air discharge releases air when pipelines are fully-charged

- Surge relief prevents pipeline bursts during pump trip & rapid pipeline filling

- NSF61 approved; ARRA, Buy America or PA Steel, American Iron & Steel (AIS), if specified

The Vent-O-Mat series RBX valve offers definite financial and technical advantages when incorporated as part of a holistic surge protection strategy. This includes:

- Improved alleviation of surge behaviour including reduction of:

- Surge pressure magnitudes by slowing surge velocities

- Duration of oscillation following a pump trip, as the air-valve continuously absorbs and dissipates the energies of the surge.

- Potential for reduction in size and/or quantity of conventional surge protection devices such as surge vessels etc.

- Automatic protection during initial filling when most surge protection devices are not operational.

- Holistic protection as each air valve installed has design features to automatically damp surges.

- The valve is virtually maintenance free.

"Anti-Shock" - "Anti-Surge" -

The RBX is the only air-release valve available that is supplied as standard with a mechanism that operates automatically to prevent pipeline damage from the high induced pressure transients associated with high velocity air discharge. Surge resulting from liquid column separation and liquid oscillation is dramatically reduced as an automatic function of this mechanism.

Performance -

The RBX has been designed and developed to provide the optimum usable and safe performance relative to all functions. Selection data has been substantiated through CSIR and other testing and can therefore, be confidently referenced.

Quality -

The RBX economically offers the highest quality construction and materials available in an air release and vacuum break valve. Stringent manufacturing and test procedures are maintained to ensure the best possible service and reliability is given by every valve produced.

Serviceability -

The RBX design facilitates extreme ease of service and maintenance. Components are in corrosion free materials to allow problem free disassembly and reassembly even after many years of operation. All maintenance spares are replaceable without special tools or skills.

Vacuum Break -

The RBX series' large orifice diameters equal the nominal size of the valve, i.e., a DN200 (8") valve has a DN200 (8") orifice. This ensures the least possible resistance to the intake of air and consequently the least possible negative pressure within a draining pipeline.

Compactness -

Although extremely robust the RBX valve's lightweight and compact construction offers handling transport and installation advantages.

Typical Applications

Surge and Waterhammer Protection

Surge Protection - Initial Filling

The RBX incorporates the additional floating "Anti-Shock" Orifice which is aerodynamically engineered to throttle air discharge when water approach velocity would otherwise become too great and induce an unacceptable pressure rise. The air throttling action increases resistance to the flow of the approaching water which consequently decelerates to a velocity which reduces the pressure rise when the valve closes . Vent-O-Mat series RBX is an essential precaution for pipeline priming.

Surge Protection -Pump Trip Conditions

In instances where a pipeline experiences water column separation due to pump stoppage, high shock pressures can be generated when the separated water column rejoins.

The Vent-O-Mat series RBX takes in air through the unobstructed large orifice when water column separation occurs, but controls the discharge of air through the "Anti-Shock" Orifice as the separated column commences to rejoin. The rejoining impact velocity is thereby considerably reduced to alleviate high surge pressures in the system

Other surge control measures may, dependent on pipeline profile, diameter and operating conditions, be needed to provide the primary surge alleviation function with the Vent-O-Mat air valves forming an integral and valuable addition in a combined strategy for further reducing surge pressures. The benefit of the "Anti-Shock" Orifice can be readily demonstrated by suitable surge modelling software.

Surge Protection - Pipeline Operating

The operation of valves and similar flow control devices can cause high-pressure transients in an operating pipeline.

The unique, single chamber design of the Vent-O-Mat series RBX valve enables a pocket of air to be trapped in the valve chamber. Automatic operation of the small orifice control float regulates the volume of air entrapped.

The volume maintained in the valve will provide a cushioning benefit to the pipeline for short duration transient pressure "spikes". This effect can be modelled by the design engineer using suitable surge software.

Surge Protection - Primary Pipeline Surge Protection Failure

In instances where air vessels or other alleviation measures are utilized as primary surge protection and these devices fail, excessively high surge pressures will be generated. The same is true if pipeline demands are increased with time without the upgrading of initial surge protection equipment.

Protection by Vent-O-Mat Series RBX will provide the benefits already described. The valve in addition, has a pipeline over pressure safety feature which acts as a "rupture-disc". Operation of this feature will be without an explosive effect and without damage to valve. This feature consists of easily replaceable components such as gaskets and seals. This feature will thus provide surge alleviation in instances where surge pressures are abnormally high. The net alleviation effect can be taken into account by the design engineer using surge modelling software.

Computer Modelling

The effectiveness of Vent-O-Mat series RBX has been substantiated by independent third party testing and by thousands of applications globally. Effective computer modeling, based on practical tests, has been ensured in the well-known and respected commercially available SURGE 2000 surge analysis software programme. Accurate results are also obtained by other commercially available surge analysis software programmes such as FLOWMASTER, TRANSAM, WATHAM andAFT Impulse.

Holistic Surge & Water Hammer Protection

Vent-O-Mat forms an integral part of a well planned, holistic surge protection strategy that should, according to application needs and financial constraints, include surge vessels, check valves, control valves and/or any other equipment needed to alleviate unacceptable surge behaviour.

Technical Data

Operation

VENTING OF A FILLING PIPELINE (EXCESSIVE WATER APPROACH VELOCITY)

In reaction to increased air flow, Float (6) closes the Large Orifice (1) and air is forced through the “Anti-Shock” Orifice (8) resulting in deceleration of the approaching water due to the resistance of rising air pressure in the valve.

PRESSURIZED AIR RELEASE FROM A FULL PIPELINE

Subsequent to the filling of a pipeline, liquid enters the valve Barrel Chamber (2) and the Floats (4), (5) and (6) are buoyed so that the Large Orifice (1) is closed by Float (6), the valve will then become internally pressurized. A minimal working pressure of < 0. 5 bar (7. 3 psi) acting on the relatively large area of the Orifice (1) will lock Float (6) into the closed position across the Large Orifice (1).

Disentrained air rises through the liquid and accumulates in the valve chamber, when the volume of air is sufficient to displace the liquid, Float (4) will no longer be buoyant and will gravitate downwards thereby opening the Small Orifice (7) and allowing accumulated air to be discharged into the atmosphere, as air is discharged the liquid raises Float (4) and reseals the Small Orifice (7) and prevents the escape of liquid.

VACUUM RELIEF (AIR INTAKE) OF A DRAINING PIPELINE

Simultaneous drainage of liquid from Valve Chamber (2) causes Floats (4), (5) and (6) to gravitate downwards onto the Baffle Plate (9), thereby allowing atmospheric air through the valve to rapidly displace draining liquid in the pipeline and prevent potentially damaging internal negative pressure.

Selection & Positioning

Technical Specifications

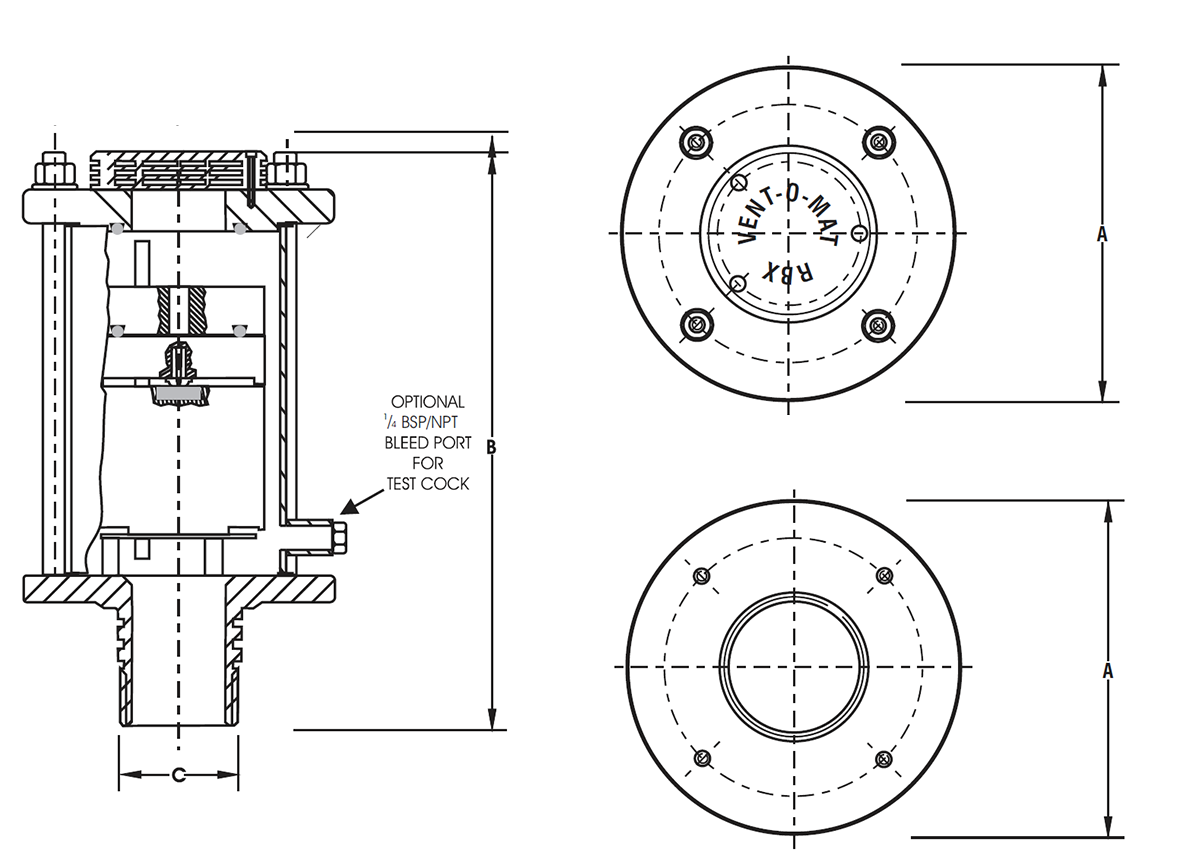

SCREWED - DN25(1") & DN50(2")

Type: Double Orifice (Small & Large Orifice) with Anti-Shock Orifice Mechanism.

Size & End Connection:

25-50mm - Male Threaded BSPT

Operating Temperature:

4 °C - 80 °C

Model Number / Operating Pressure Range:

RBX 2511 - up to 25 bar

RBX4011 - up to 40 bar

Overall Dimensions & Weights - 25-50mm

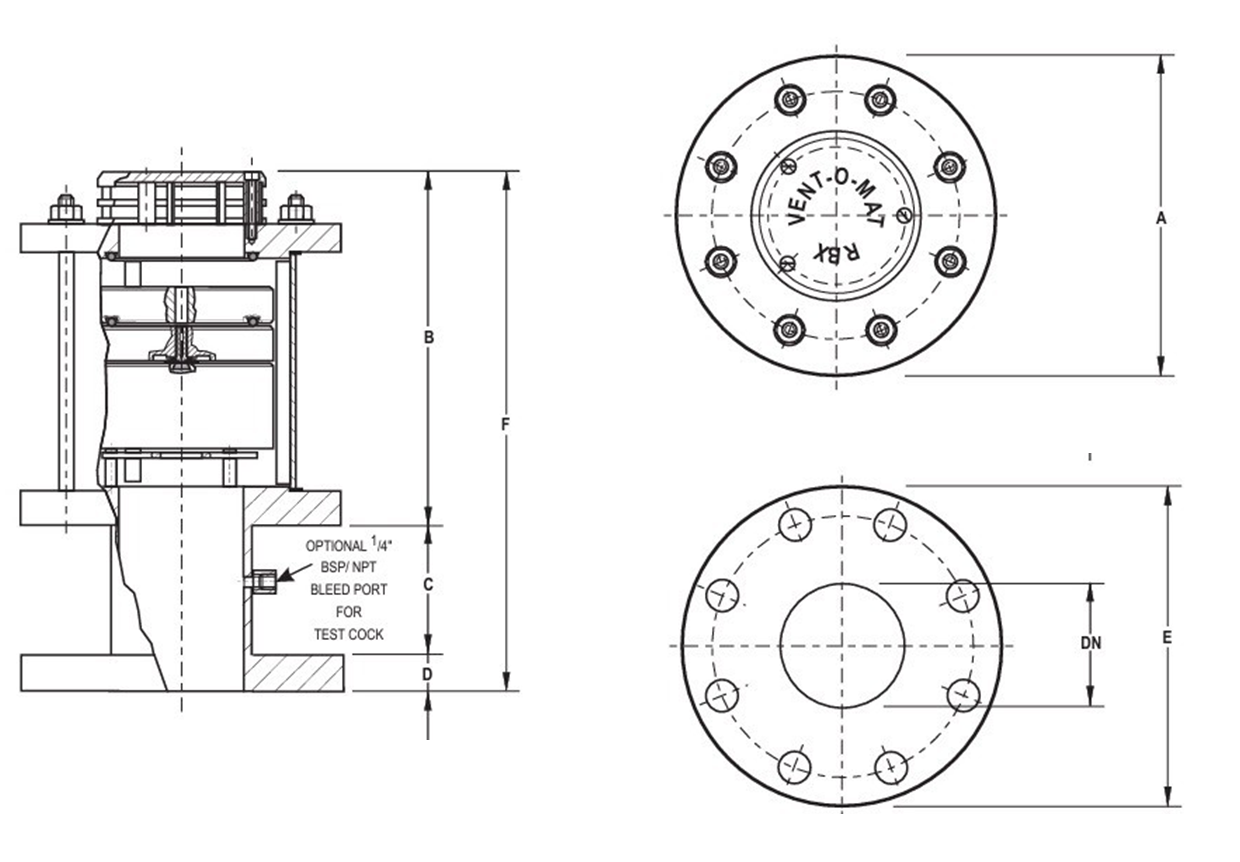

FLANGED - DN80 (3") & DN100 (4")

Type: Double Orifice (Small & Large Orifice) with Anti Shock Orifice mechanism.

Size & End Connection:

80-200mm - Flanged to AS4087 - PN16

Operating Temperature:

4 °C - 80 °C

Model Number / Operating Pressure Range:

RBX 1601 & 1631 - up to 16 bar

RBX 2501 & 2531 - up to 25 bar

RBX 4001 & 4031 - up to 40 bar

Overall Dimensions & Weights - 80-100mm

FLANGED - DN150 (6") & DN200 (8")

Type: Double Orifice (Small & Large Orifice) with Anti Shock Orifice mechanism.

Size & End Connection:

80-200mm - Flanged to AS4087 - PN16

Operating Temperature:

4 °C - 80 °C

Model Number / Operating Pressure Range:

RBX 1601 & 1631 - up to 16 bar

RBX 2501 & 2531 - up to 25 bar

RBX 4001 & 4031 - up to 40 bar

Overall Dimensions & Weights - 150-200mm

Repair Kits

| Product Code | Size | Description |

|---|---|---|

RBX025-RK |

25mm |

VOM-RBX - Repair Kit |

RBX050-RK |

50mm |

VOM-RBX - Repair Kit |

RBX080-RK |

80mm |

VOM-RBX - Repair Kit |

RBX100-RK |

100mm |

VOM-RBX - Repair Kit |

RBX150-RK |

150mm |

VOM-RBX - Repair Kit |

RBX200-RK |

200mm |

VOM-RBX - Repair Kit |

Vent-O-Mat - RBX - Air Release Valves

For water pipeline applications. High performance, full porting for maximum vacuum protection.

Vent-O-Mat - RBX100-1641

| Product Code | Size | Pressure Rating | Description |

|---|---|---|---|

RBX025-2511 |

25mm |

25 Bar |

Antishock, Combination ARV - 265mm Height - Threaded Male BSP |

RBX050-2511 |

50mm |

25 Bar |

Antishock, Combination ARV - 325mm Height - Threaded Male BSP |

RBX080-1641 |

80mm |

16 Bar |

Antishock, Combination ARV - 425mm Height - Flanged |

RBX100-1641 |

100mm |

16 Bar |

Antishock, Combination ARV - 322mm Height - Flanged |

RBX150-1641 |

150mm |

16 Bar |

Antishock, Combination ARV - 612mm Height - Flanged |

RBX200-1641 |

200mm |

16 Bar |

Antishock, Combination ARV - 672mm Height - Flanged |

BSP to Flange Adaptor

Flange SS PS50

| Product Code | Size | Description |

|---|---|---|

Flange SS PS50 |

50mm |

Female BSP to Table D Flange Adaptor |